Understanding Modes and States in Kanoa Ops

In manufacturing and operational management, the concepts of "Mode" and "State" play a crucial role in defining and understanding the performance and status of machinery and production lines. In Kanoa MES, these concepts are implemented to provide detailed insights and control over the production process. This article will delve into what a Mode is, what a State is, their differences, and how they are used within Kanoa MES.

What is a Mode?

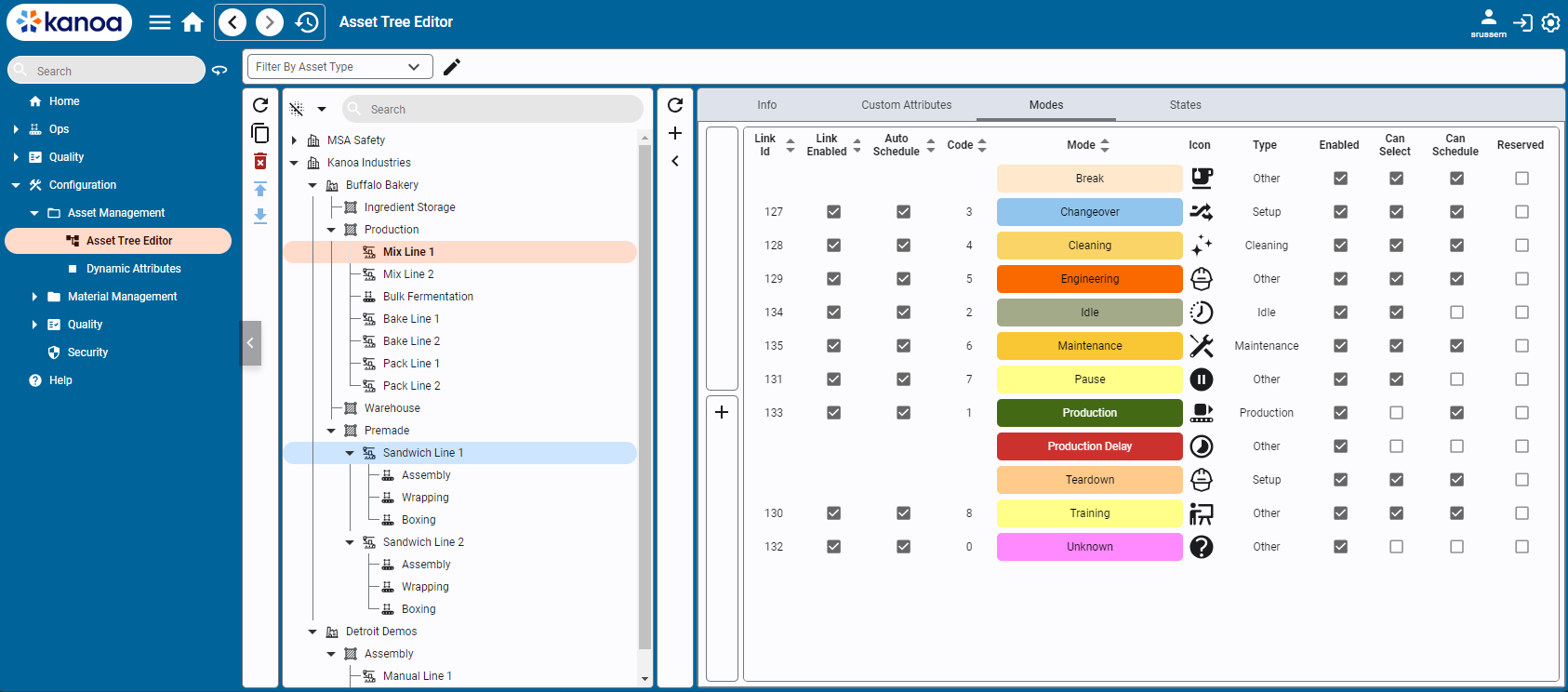

Mode Configuration in Kanoa Ops 1.4

A Mode in Kanoa MES refers to a predefined operational context for a machine or production line. It defines what the machine is supposed to be doing at any given time. Modes are used to categorize the different activities or phases that a machine goes through during its operational cycle. Examples of modes include:

- Production Mode: When the machine is actively producing parts or products.

- Maintenance Mode: When the machine is undergoing maintenance activities.

- Idle Mode: When the machine is not in use but is ready to be started.

- Setup Mode: When the machine is being prepared for production, such as during tool changes or adjustments.

Modes are essential for scheduling and tracking purposes. They allow the system to understand the expected activities and allocate time and resources accordingly. In the Kanoa MES, modes are often scheduled, meaning that the system can switch between different modes based on a predefined timetable.

What is a State?

State Configuration in Kanoa Ops 1.4

A State in Kanoa MES, on the other hand, refers to the real-time status or condition of the machine as it operates within a given mode. States provide feedback on what is actually happening with the machine at any moment. Examples of states include:

- Running: The machine is actively operating and performing its tasks.

- Stopped: The machine has ceased operation, either due to a planned stop or an unexpected issue.

- Fault: The machine has encountered an error or malfunction.

- Waiting: The machine is waiting for input, materials, or other necessary conditions to proceed.

- MTR204 Faulted: The machine has encountered an error or malfunction, and this is the cause of the downtime.

States are dynamic and can change frequently as the machine operates. They provide granular details about the machine's performance and any issues that may arise during production.

Each state also has a State Type, which can be Running, Planned Downtime, or Unplanned Downtime. Tracking critical downtime events and machine faults as States is a key-function in Kanoa Ops and provides data for our OEE Calculations and Downtime Reports.

Modes vs. States

Determining whether something should be classified as a mode or a state in Kanoa MES often depends on how you want to interpret and analyze your data. A prime example of this is deciding whether a break should be considered a mode or a state.

- Break as a Mode: If a break is considered a mode, it can be scheduled and does not count against the productivity of a production event. This means that when a break is issued, the system moves out of the production mode and into the break mode, treating it as a planned event that does not affect the overall efficiency of the production run.

- Break as a State: Alternatively, if a break is considered a state, the machine remains in the production mode, but the break is categorized under a planned or unplanned downtime state type. This approach counts the break time against the availability and efficiency of the production mode, highlighting that the machine was not producing during that period.

The choice between these approaches depends on your operational goals and how you prefer to represent production efficiency. If you want to exclude break times from production efficiency calculations, treating breaks as a mode is more suitable. However, if you want to include break times to reflect the actual time the machine was not producing, treating breaks as a state is more appropriate.

Our own Jason Coope summed it up well: “I tend to use Modes for things like Maintenance or Cleaning that happen outside of a Production Run, and states for the things I want to track during a Production Run.”

How Modes and States are Used in Kanoa MES

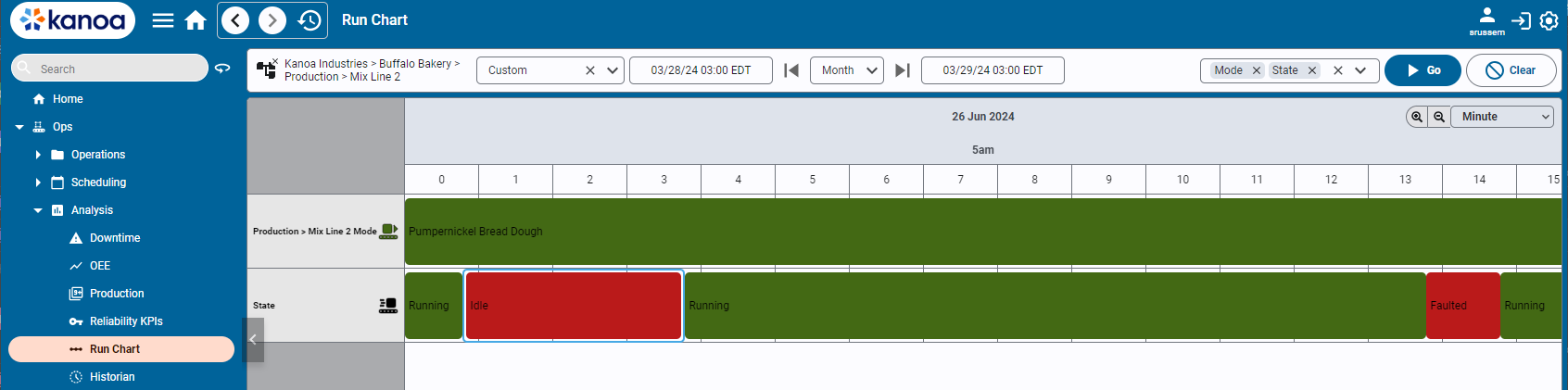

The Kanoa Ops Run Chart tool visualizes Mode and State events

In Kanoa MES, both modes and states are integral to managing and optimizing production processes. Here's how they are used:

- Scheduling and Planning: Modes are used to schedule different activities for the machines. For example, a production mode might be scheduled from 9 AM to 5 PM, while maintenance mode might be scheduled from 5 PM to 7 PM.

- Real-Time Monitoring: States are monitored in real-time to understand the exact condition of the machine. This allows for quick responses to any issues, such as stopping production if a fault state is detected.

- Performance Tracking:

- By analyzing the states within each mode, Kanoa MES can provide detailed reports on machine performance. For example, it can show how much time the machine spent in a running state versus a stopped state during the production mode.

- By analyzing the modes, Kanoa MES can provide insight into the utilization of your assets, such as how much time is spent in changeover or maintenance or just sitting idle, which can aid in capacity planning.

- Data-Driven Decisions: The combination of modes and states data helps in making informed decisions. For instance, you may want to entirely ignore unplanned downtime states during modes like Maintenance as they could indicate normal work procedures or process adjustments; while those same states are critical information during a Production mode.

Example Scenario

Consider a production line scheduled to operate in production mode from 8 AM to 4 PM. During this period, the machine goes through various states such as ‘running’, ‘waiting for materials’, and ‘stopped due to minor fault’. Here's how Kanoa MES manages this:

- Mode: The system knows that from 8 AM to 4 PM, the machine should be in production mode.

- State: Throughout this period, the system records the machine's states. At 8:00 AM, the state is running. At 10:15 AM, the state changes to waiting due to material shortage. At 10:30 AM, the state returns to running after materials are supplied. At 11:45 AM, the state changes to fault due to a minor issue, and at 12:00 PM, it is back to running after the issue is resolved.

This detailed tracking enables the system to provide comprehensive reports on how efficiently the machine operated during the production mode and highlight areas for improvement.

Conclusion

Modes and states are fundamental concepts in Kanoa MES that help in effectively managing and optimizing manufacturing processes. By understanding the difference between them and how they are used, manufacturers can gain better control over their operations, leading to improved efficiency and productivity.

You May Also Like

These Related Stories

%20(1)-1.png)

Material Management in Kanoa MES

What's in a name? Findings and Conclusions

No Comments Yet

Let us know what you think