END-TO-END TRACK AND TRACE

Kanoa Trace

Traceability and genealogy for compliance, quality control, and continuous improvement. Track raw materials, inventory, work-in-progress, and finished goods throughout the manufacturing lifecycle. Generate real-time trace graphs to analyze the genealogy of every product, providing unparalleled visibility into production processes and enabling swift root-cause analysis and regulatory reporting.

Kanoa Trace is an add-on solution and requires Kanoa Ops.

End-to-end genealogy without custom reinvention

Kanoa Trace provides a consistent approach to tracking material consumption, transformation, and product history—enabling faster investigations, audit readiness, and customer compliance.

Raw Material, WIP, and Finished Goods

Track material throughout the entire manufacturing process

Digital Records

Replace unreliable paper-based tracking with real-time digital systems

Compliance and Continuous Improvement

Demonstrate compliance and identify improvement opportunities with real-time data

Kanoa Trace Features

Configure for your Process

Define your process your way, including lot operations, lot naming, and serialization

Regulatory Compliance

Produce audit trails for how every product was made

Recall Response

Respond to recalls and complaints with real-time data

Inventory Management

Real-time and historical analysis

Mass Balance

Account for every ounce. Maintain precise material accountability.

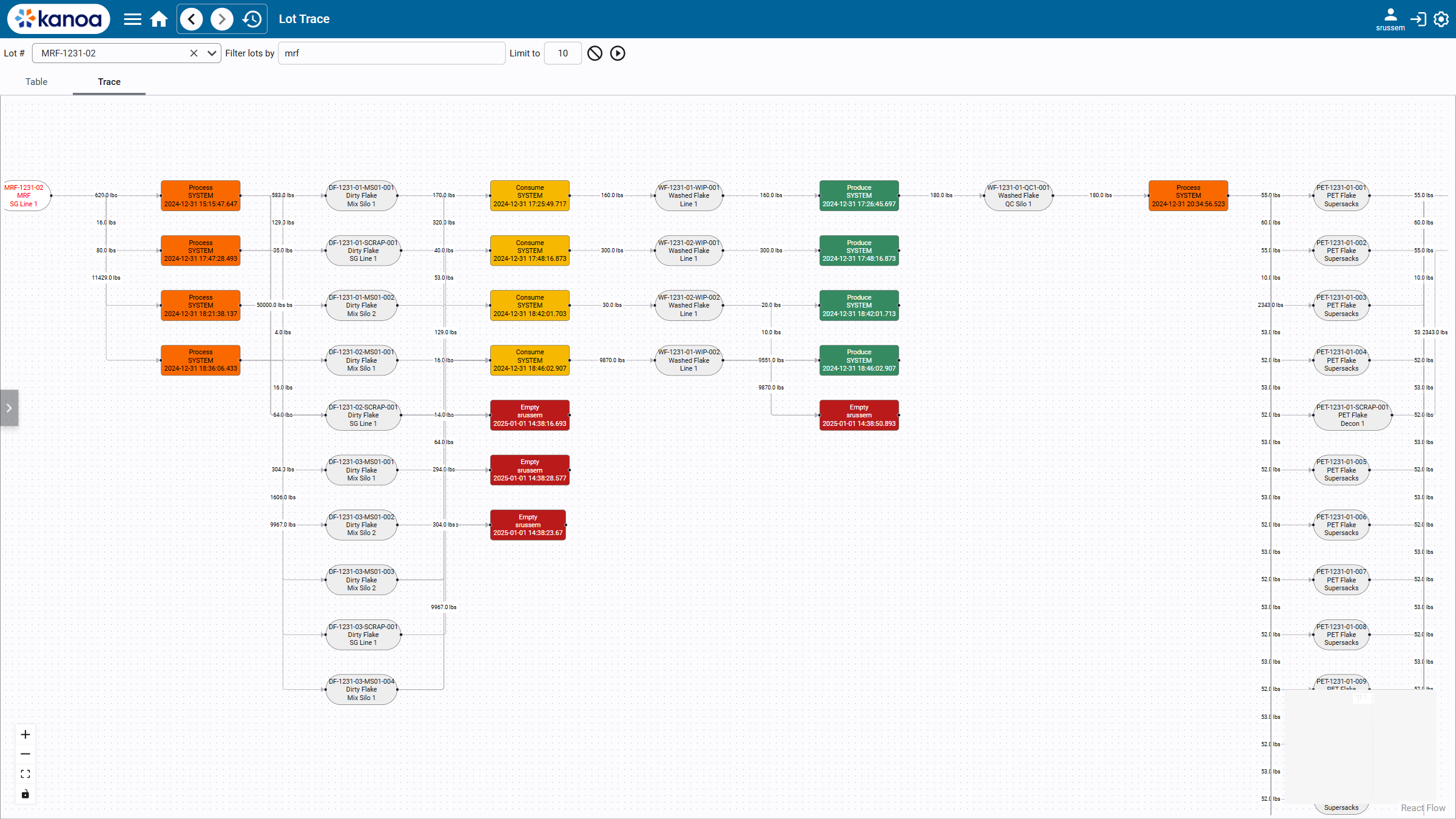

Trace Graph

Continuous Improvement

Genealogy for root-cause analysis

Automated and Manual Data

Collect data from equipment or operators

ERP Integration

Bidirectional coordination with ERP and other business systems

Kanoa MES Integration

Coordinated production orders, shifts, OEE, and quality forms

Control Quality

Identify and mitigate quality issues before they propagate

Barcode Integration

Leverage barcodes, RFID, and other material identifiers

Built on an operational execution context

Kanoa Trace relies on Kanoa Ops for asset hierarchy, material definitions, and work order execution context—so trace events are grounded in real production workflows.

Let's take a tour

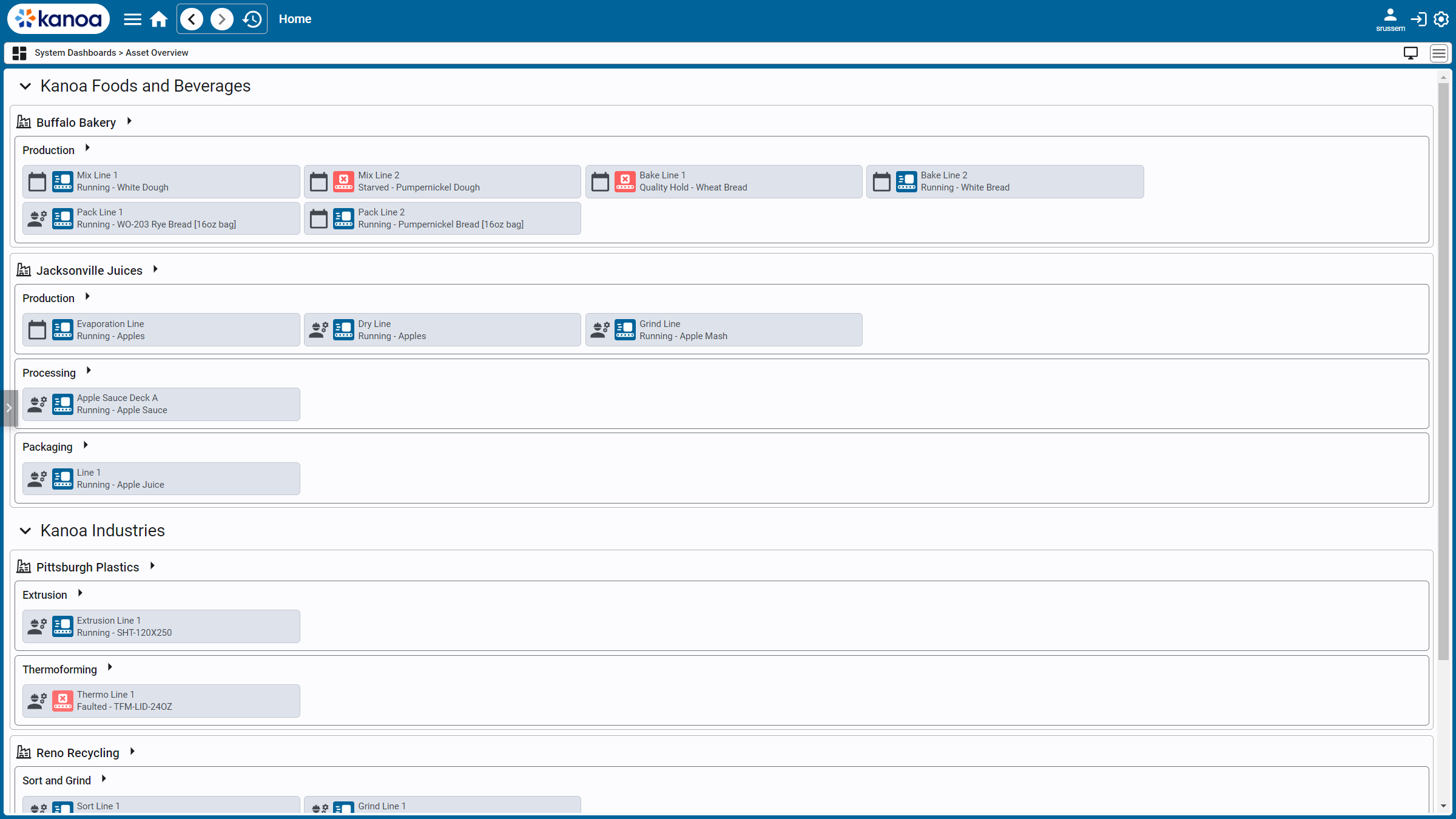

Asset Overview

Your entire Enterprise and Factory, all in one place. See what's running on each asset and its current production state.

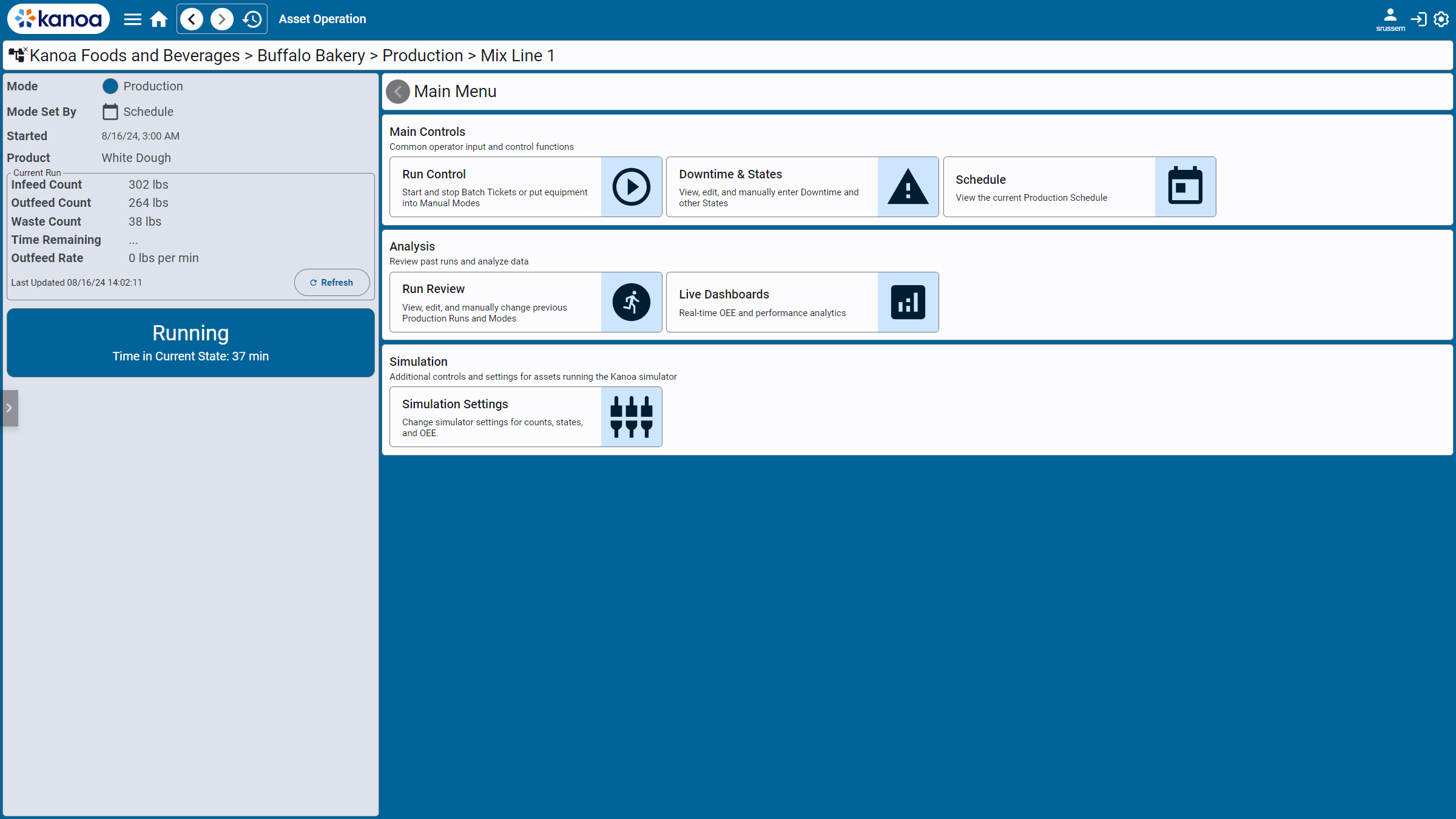

Asset Operations Home

Your one-stop-shop for all your daily Asset Operation needs. Manage and control production assets from this one simple screen.

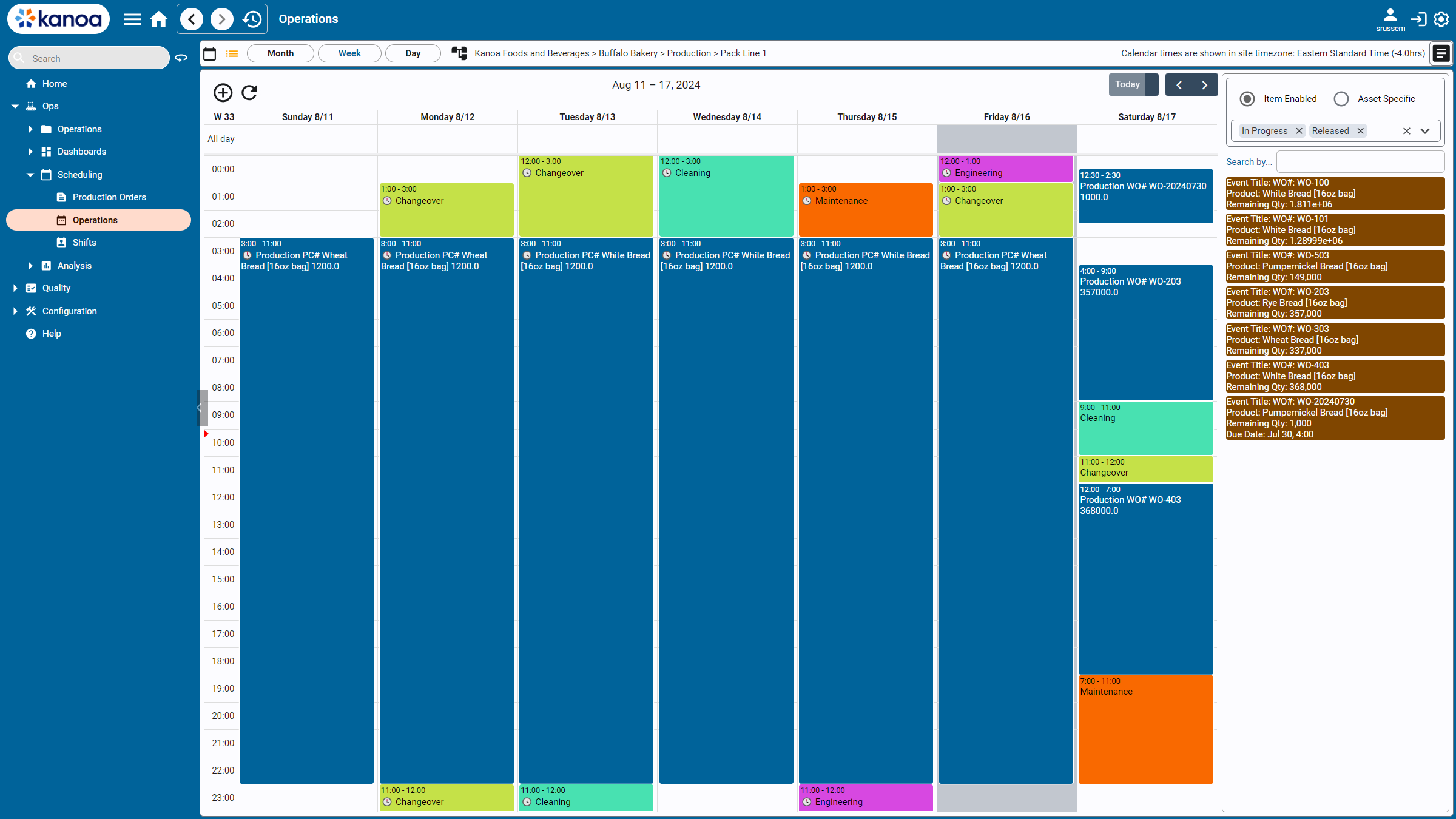

Production Scheduling

Set production schedules, drag-and-drop work orders, and manage non-production modes like Maintenance and Changeovers.

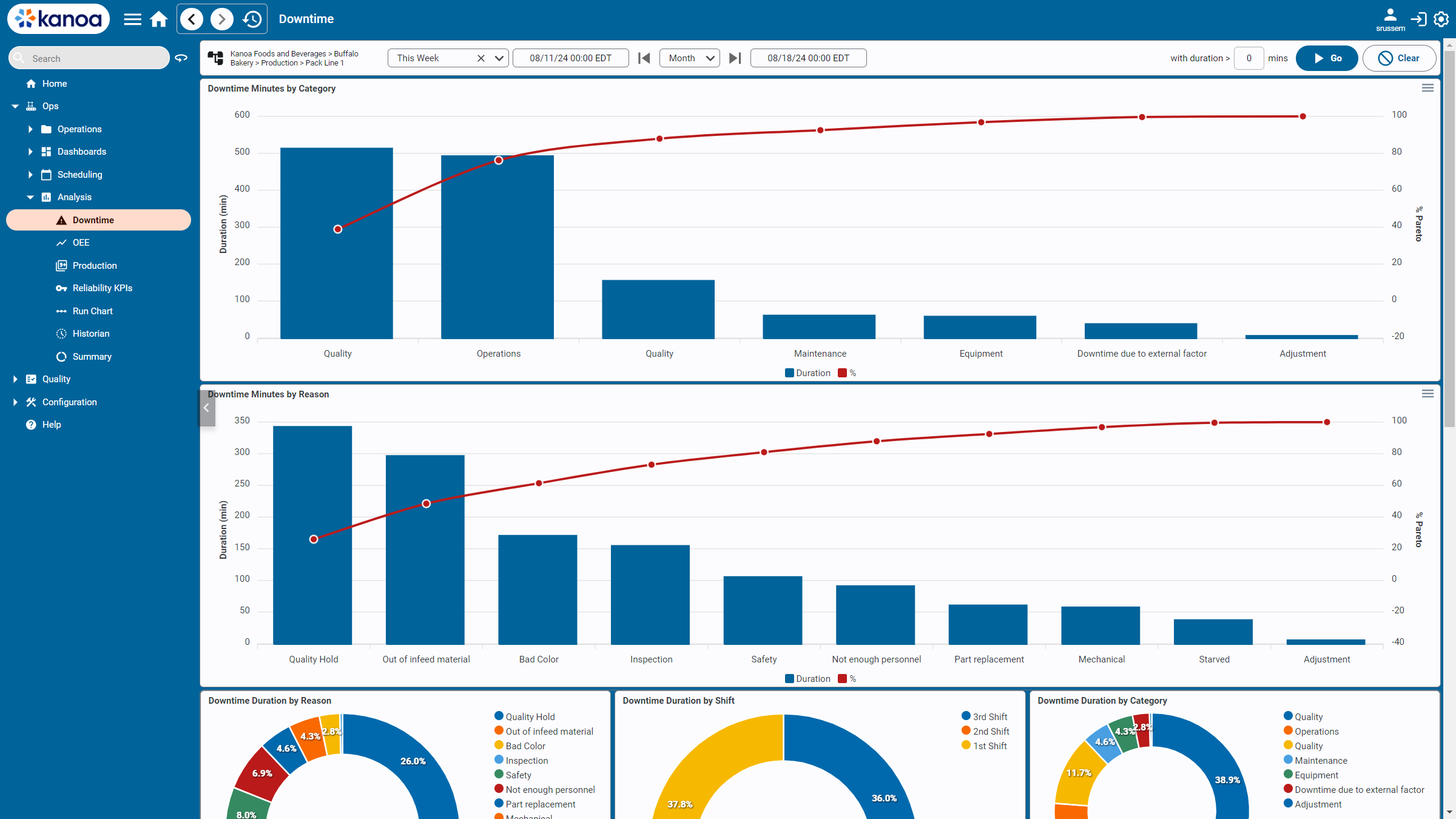

Downtime Analysis

Analyze unplanned downtime by asset, time, reason code, category, shift, and more.

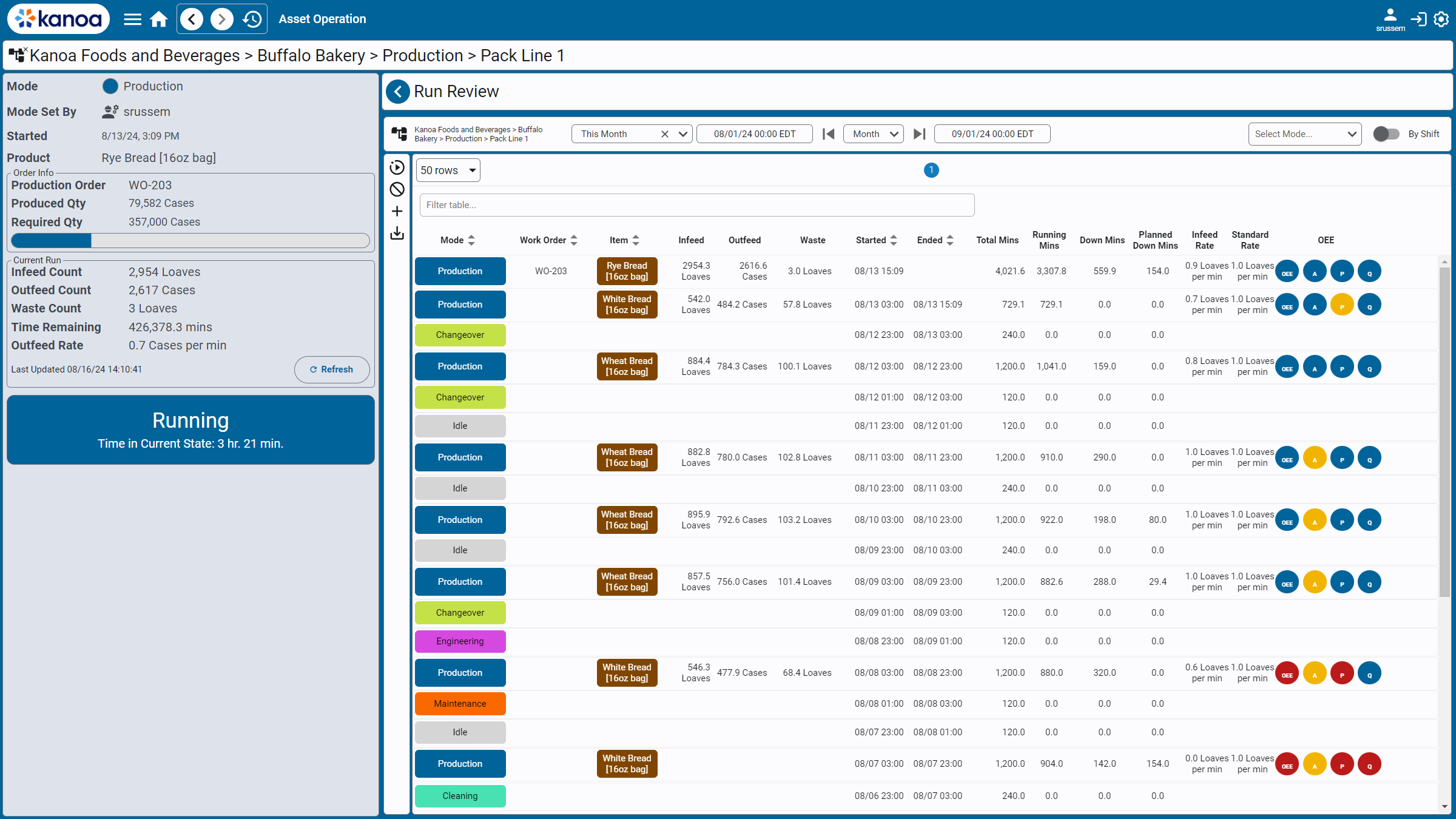

Run Review

View a every Production and Non-Production Event that occurred on the Asset, along with Production Counts and OEE KPI data.

Asset Cards

At-a-glance KPIs for all OEE Assets in an Area or Plant. Check out production status, work order progress, unplanned downtime, and OEE all in one place.

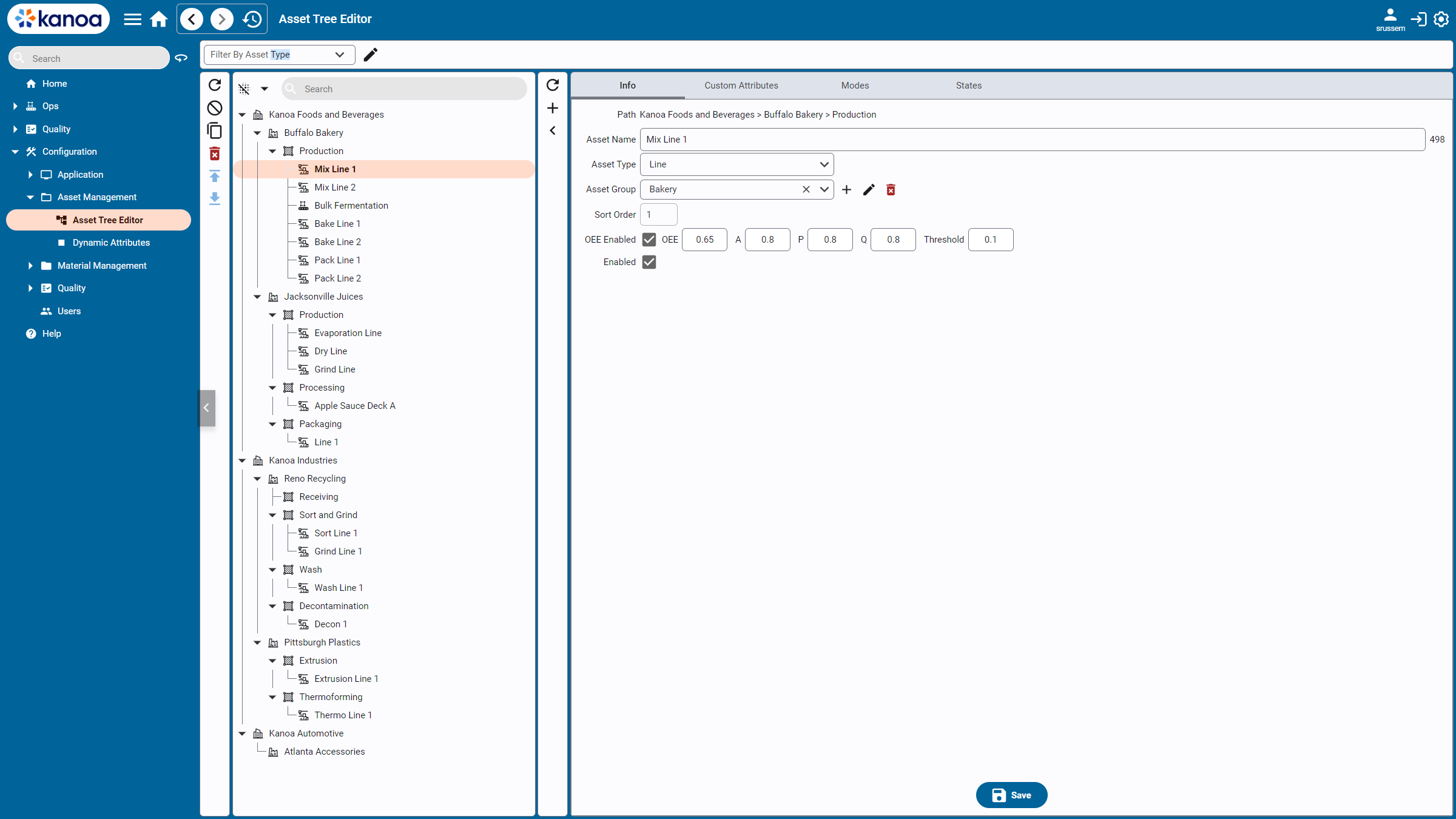

Configure Assets

Organize your assets using the ISA-95 Hierarchy (or not!). Set assets to be OEE Enabled to schedule work and track productivity.

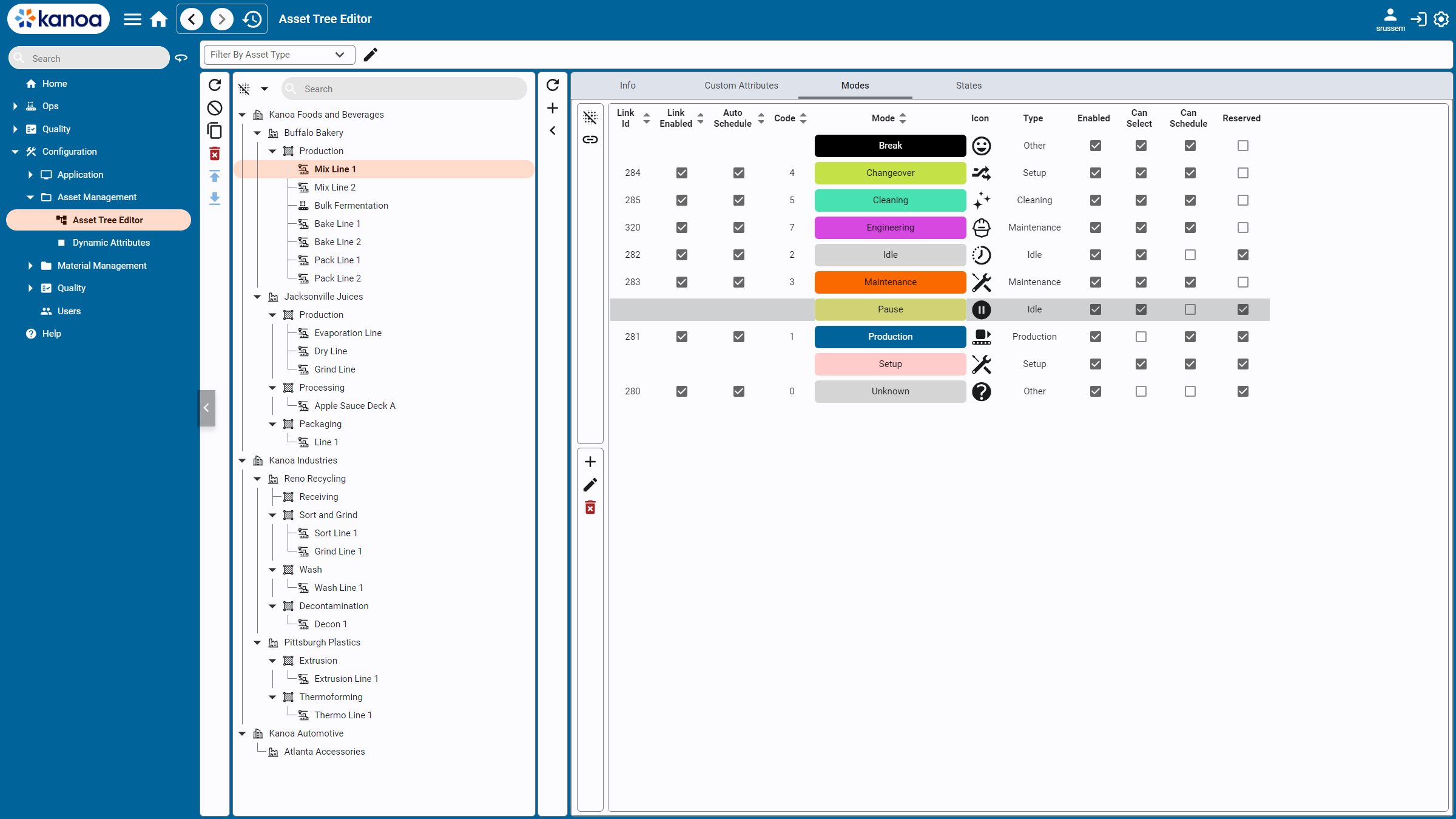

Configure Modes

Configure your list of Modes and link Modes to Assets. Modes describe what is intended to be happening on an asset.

Lot Management Concepts

Lot management involves organizing, tracking, and controlling batches of products or materials throughout their lifecycle in manufacturing, supply chain, and inventory systems. Each lot receives a unique identifier, enabling precise tracking through the entire supply chain, from production to sale or distribution. This process is essential for regulatory compliance, quality assurance, and efficient recall management.

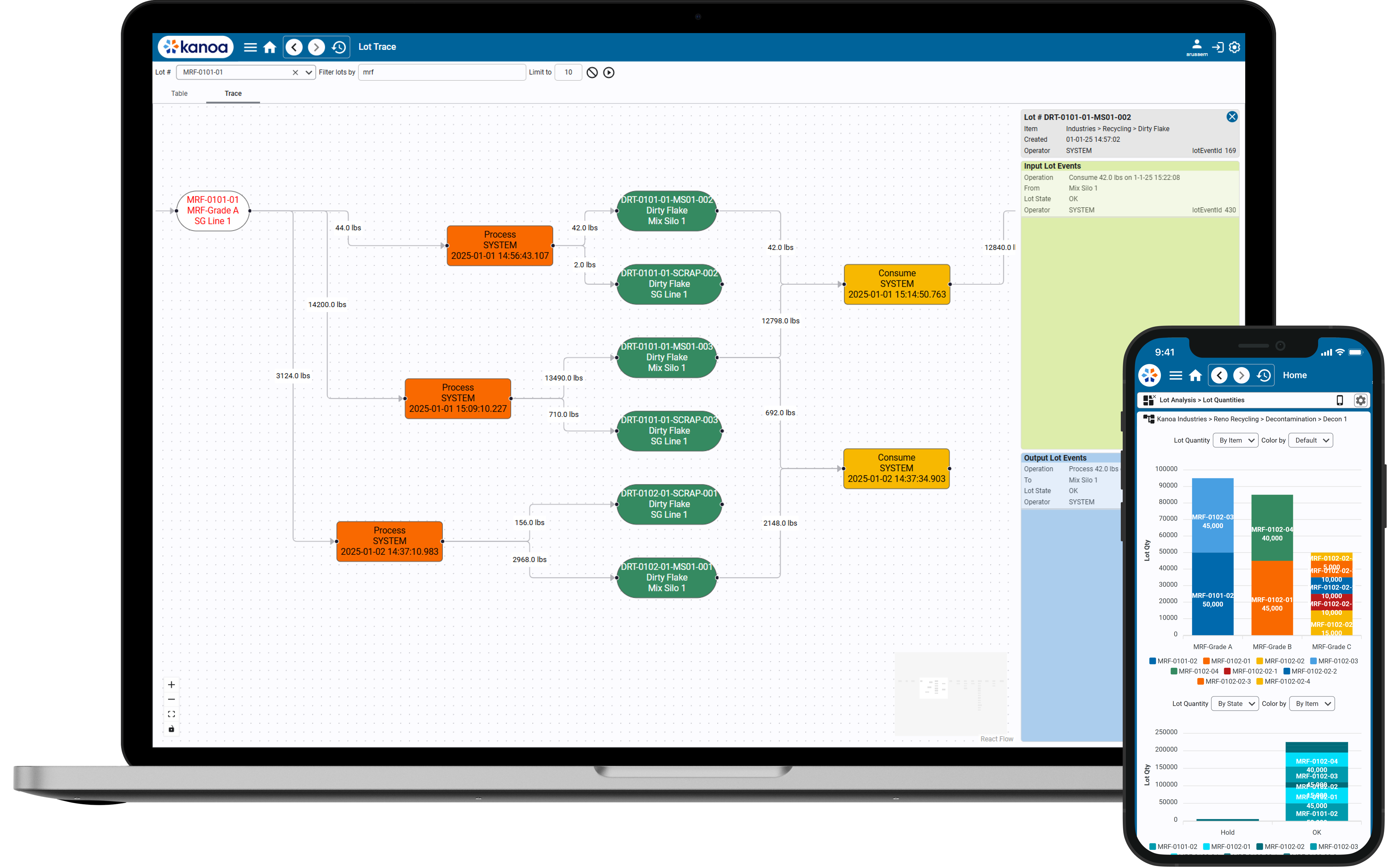

Genealogy and Analysis

The Kanoa Node Chart component enables users to visually trace all operations, lots, and events linked to a specific lot. Through Kanoa’s Asset Lot Perspective screens, users can view all active lots for a given asset, area, or the entire plant. Inventory analysis is available by state, material, quantity, date, and more, providing detailed insights to optimize operations.

Lot Operations and Events

Lot Operations describe activities that impact a lot, including receiving, transferring, splitting, and scrapping. These operations are fully configurable to align with your unique manufacturing processes. Lot Operations link one or more Lot Events, which serve as the inputs or outputs of the operation. Each Lot Event details the quantity involved, the lot state, and its source or destination.

The Digital Advantage

Replace cumbersome paper tracking sheets prone to errors with efficient digital traceability solutions. These solutions provide real-time feedback, directly impacting your bottom line. Utilize live mass balance to optimize efficiency. Generate instant genealogy reports to quickly address customer complaints, recalls, and audits, and analyze real-time inventory for better-informed operational decisions.