THE OPERATIONAL FOUNDATION FOR KANOA MES - DELIVERING OEE, DOWNTIME TRACKING, SCHEDULING, AND ORDER EXECUTION

Kanoa Ops

Kanoa Ops is the required foundation module for Kanoa MES. It provides the operational model and execution context that enables scalable MES deployments, while supporting continuous improvement through structured data capture and performance visibility.

Operations management, built for production teams

Kanoa Ops helps manufacturing teams manage daily execution while turning operational signals into continuous improvement outcomes. It standardizes how work orders, materials, assets, and operator workflows are represented in the MES layer—so you can scale across lines and sites without reinventing fundamentals.

Optimize Operations

Improve throughput with scheduling, execution visibility, and OEE reporting

Reduce Downtime

Reduce downtime through structured reason capture and operator workflows

Build your Foundation

Build an reliable foundation for Trace, Quality, and other Smart Manufacturing technology

Kanoa Ops Features

OEE Tracking

Downtime Coding

Loss Coding

Scheduling

Work Execution

Scrap Coding

Work Orders

Production Dashboards

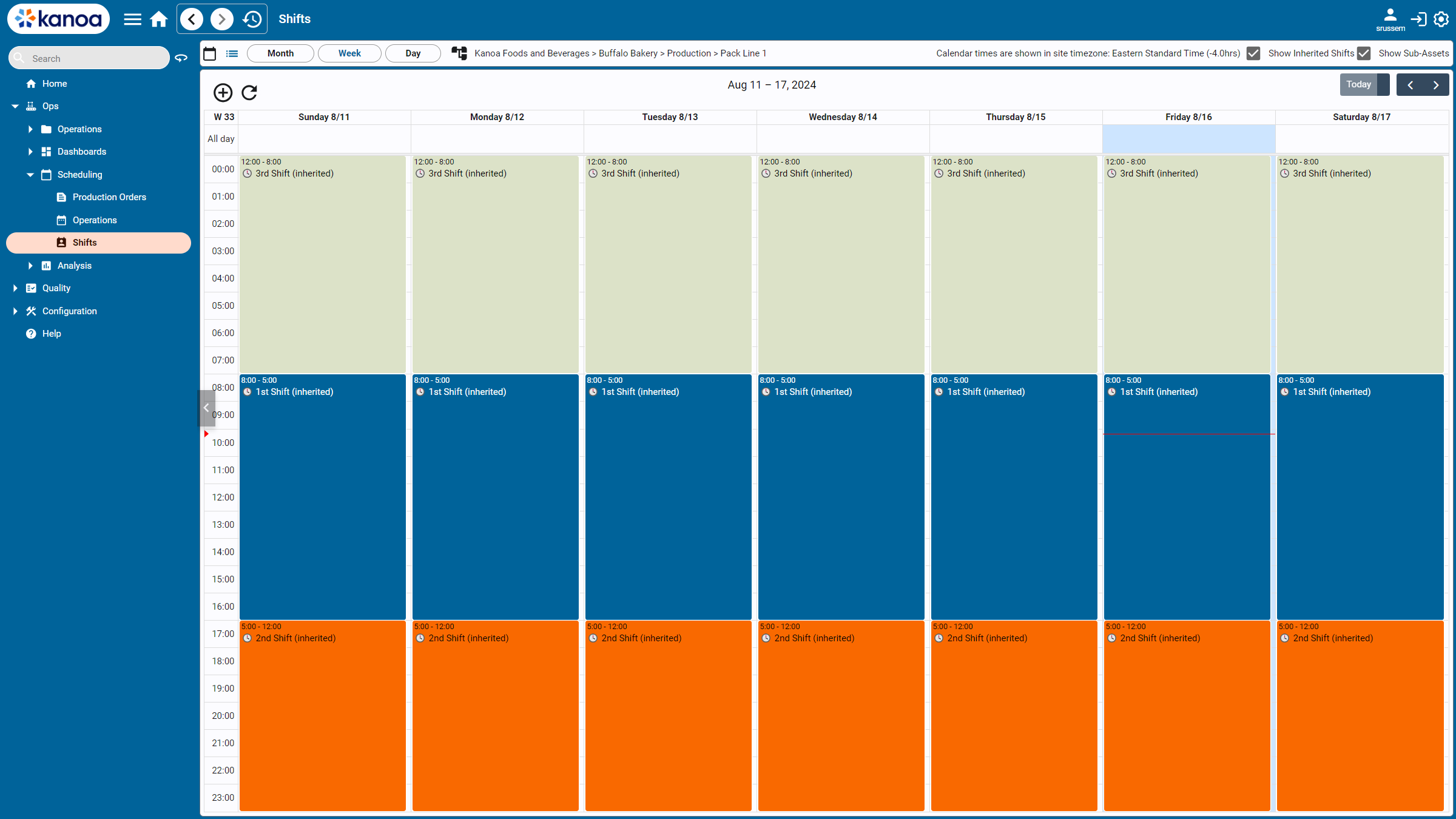

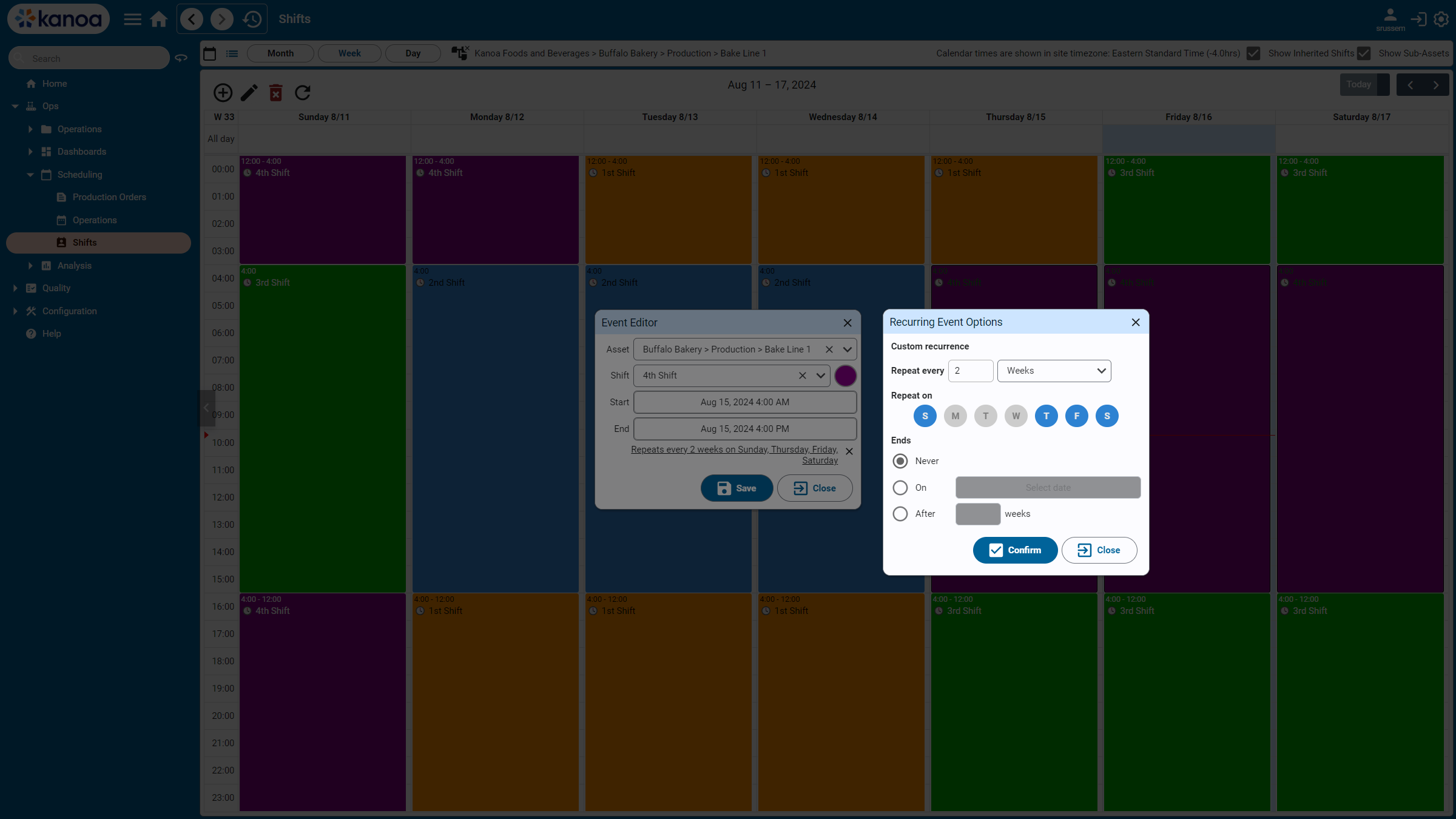

Shift Scheduling

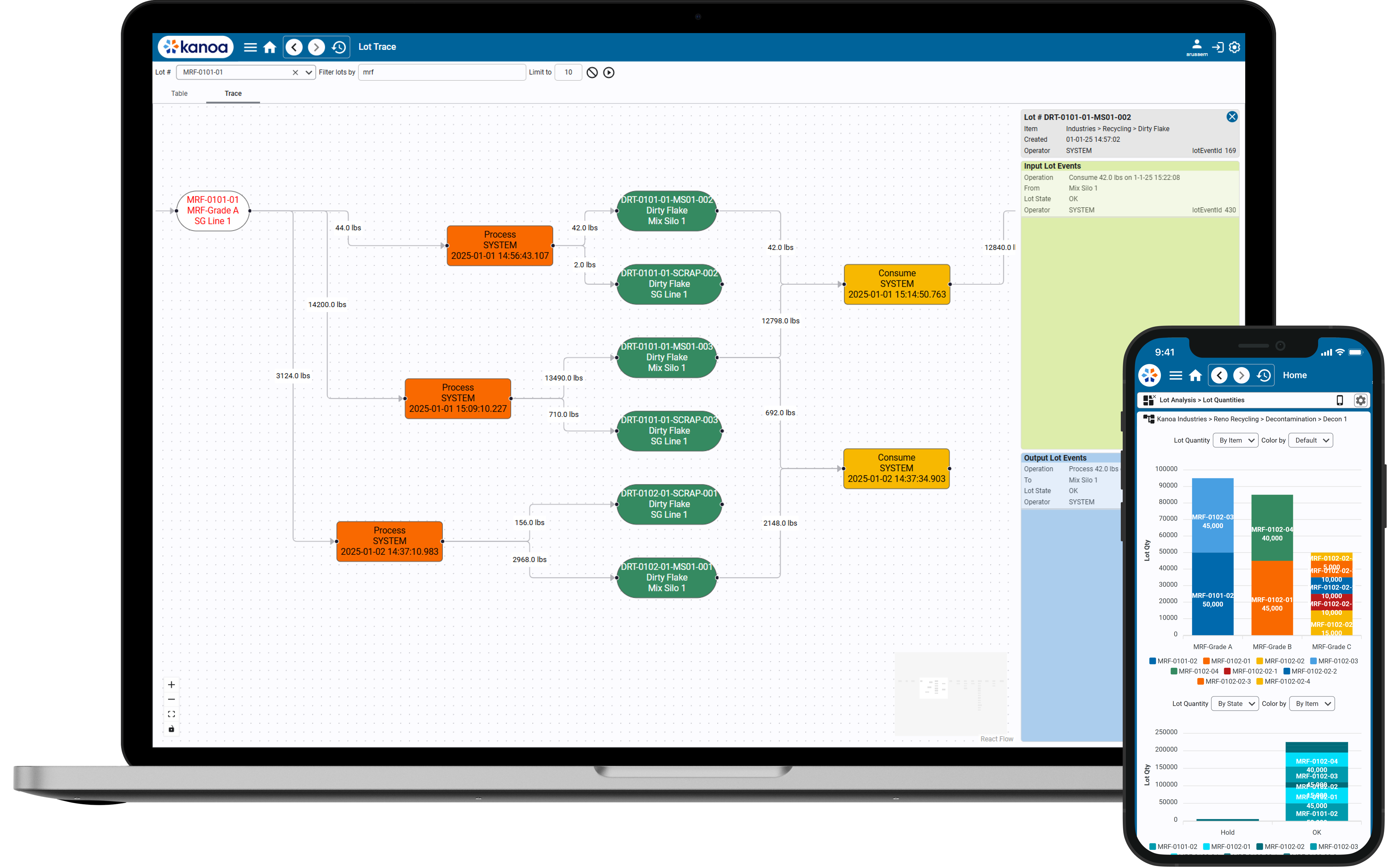

The Foundation for Trace and Quality

Kanoa Trace and Kanoa Quality build on the Ops foundation. Start with Ops to establish execution context and consistent data capture, then expand into genealogy, compliance workflows, and structured trace reporting when ready.

Let's take a tour

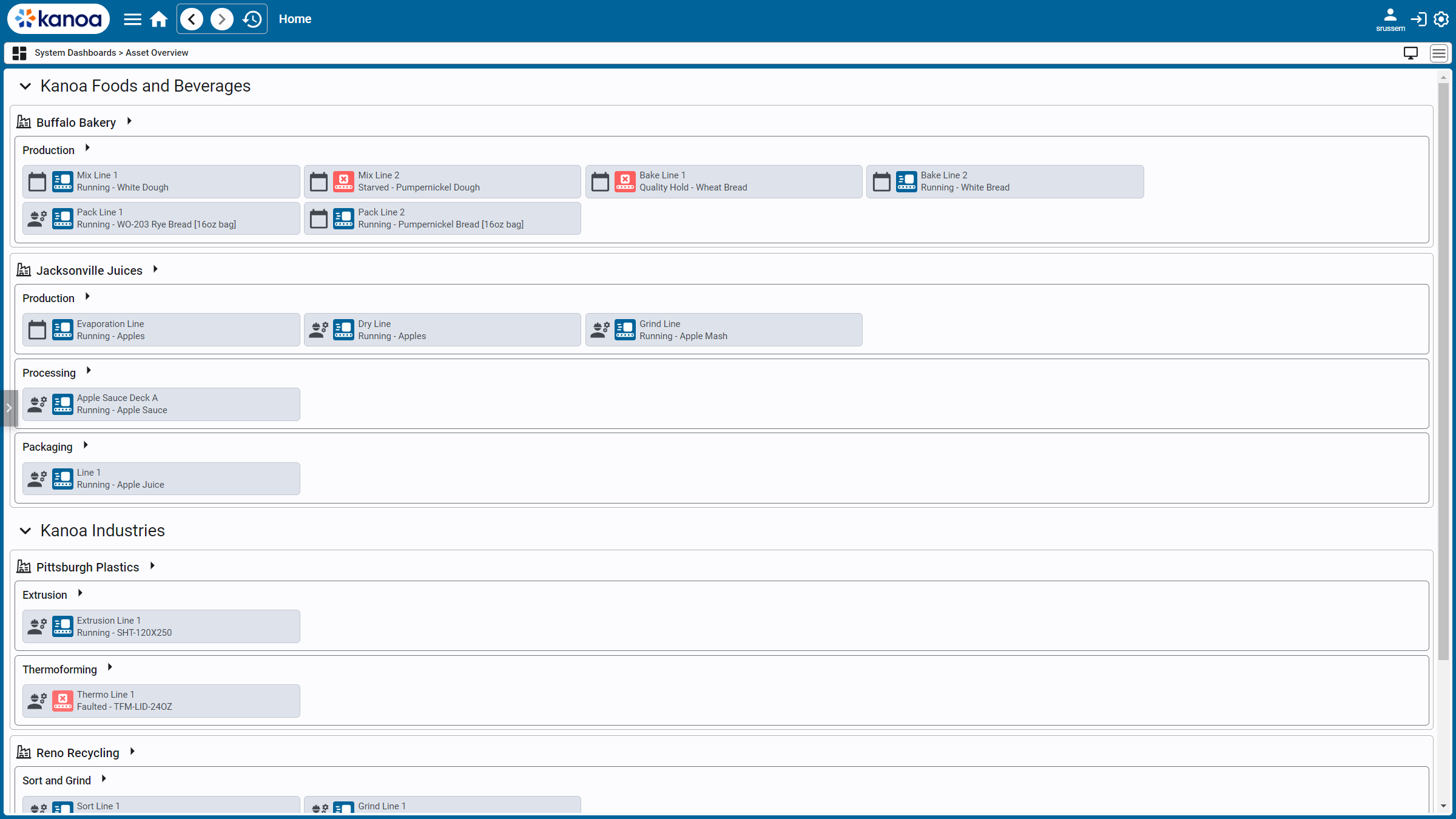

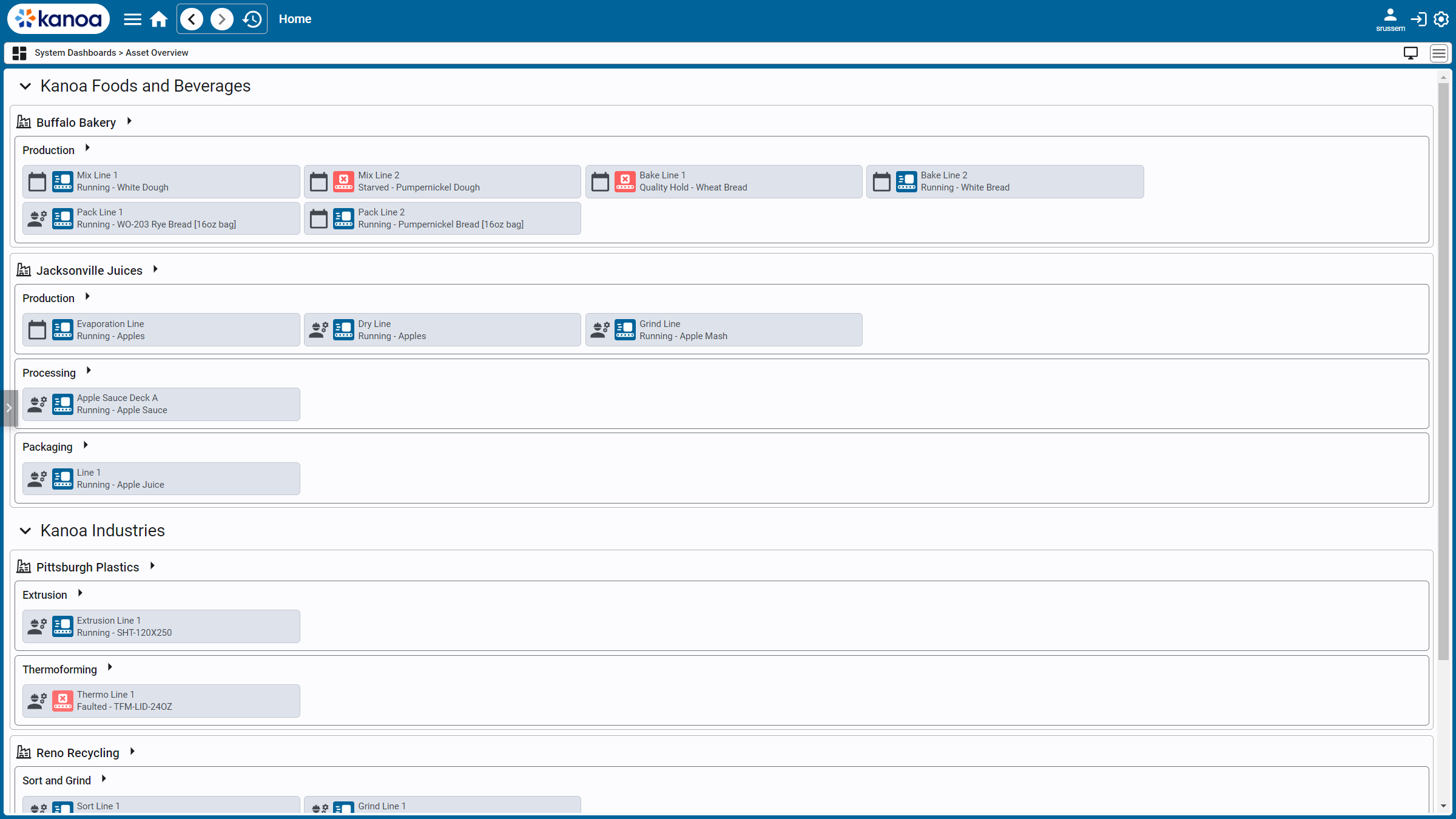

Asset Overview

Your entire Enterprise and Factory, all in one place. See what's running on each asset and its current production state.

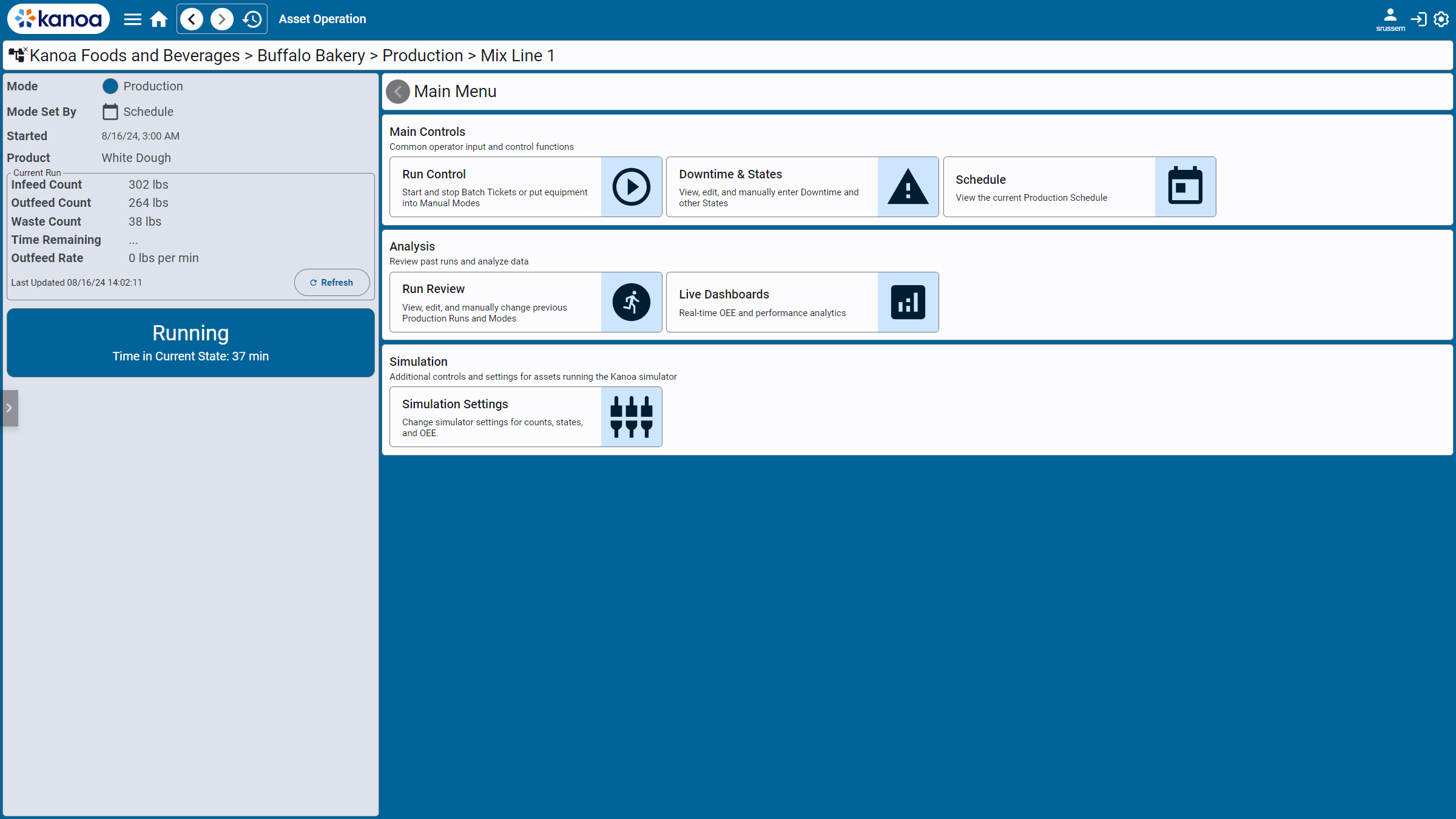

Asset Operations Home

Your one-stop-shop for all your daily Asset Operation needs. Manage and control production assets from this one simple screen.

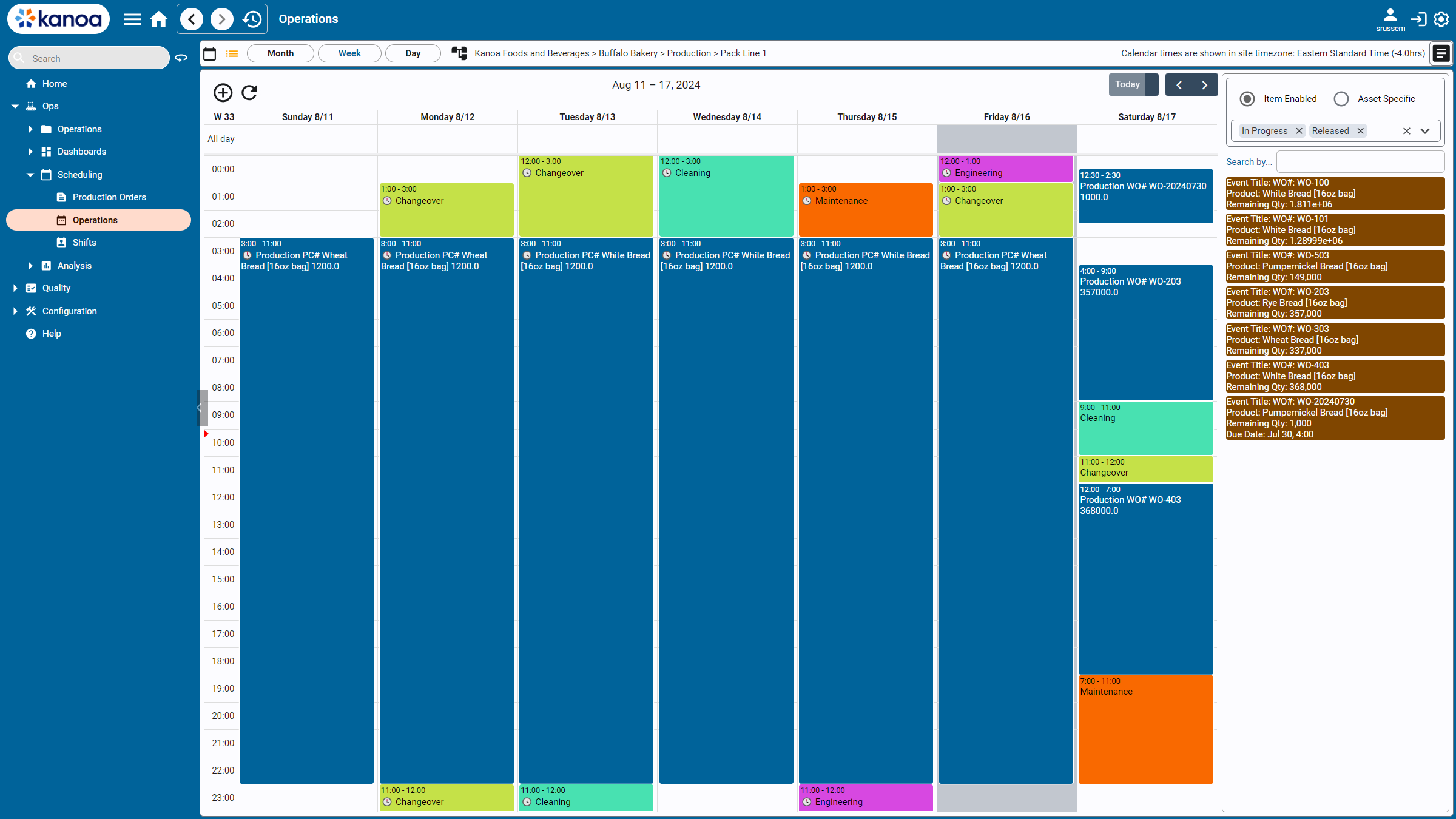

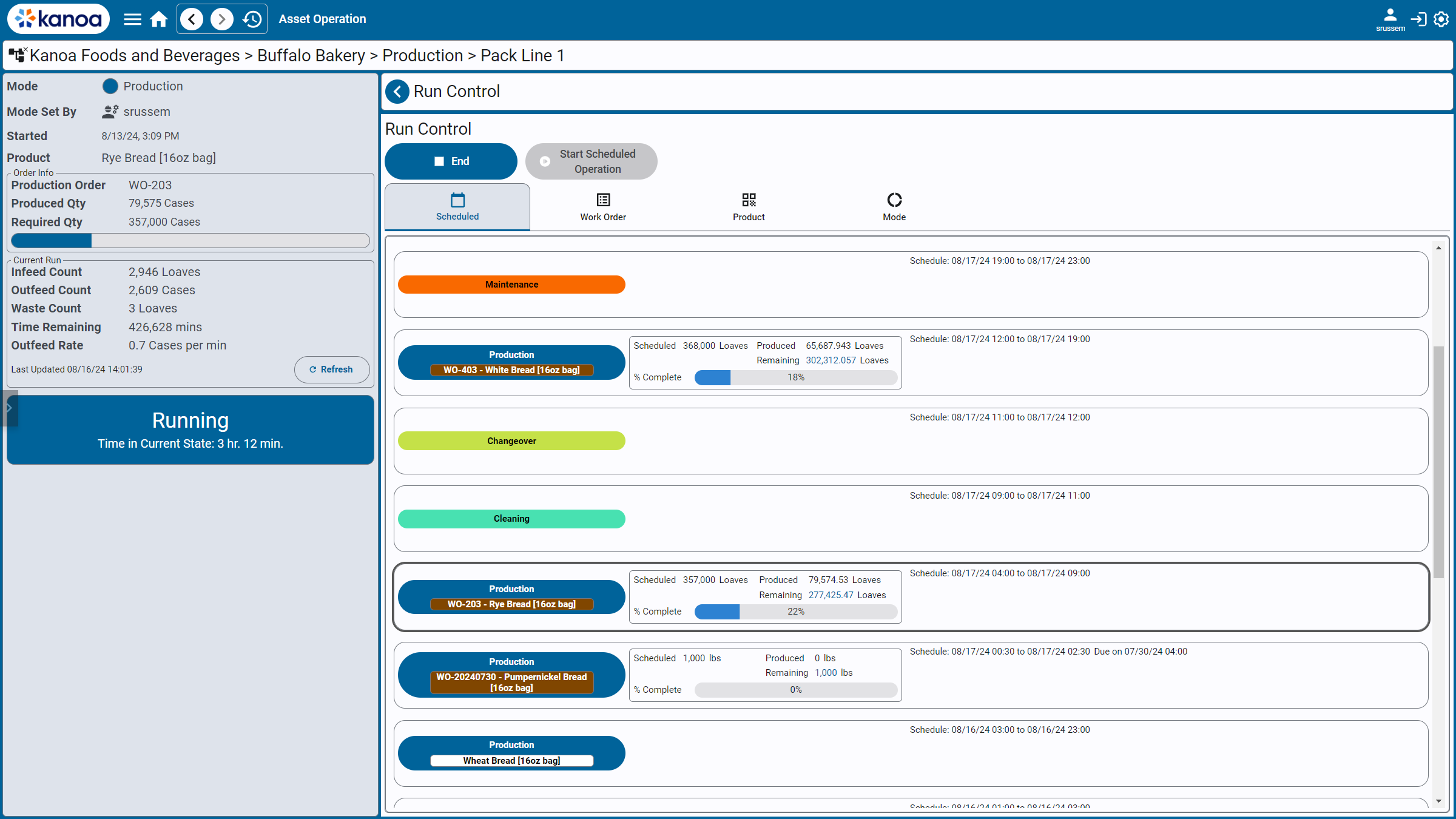

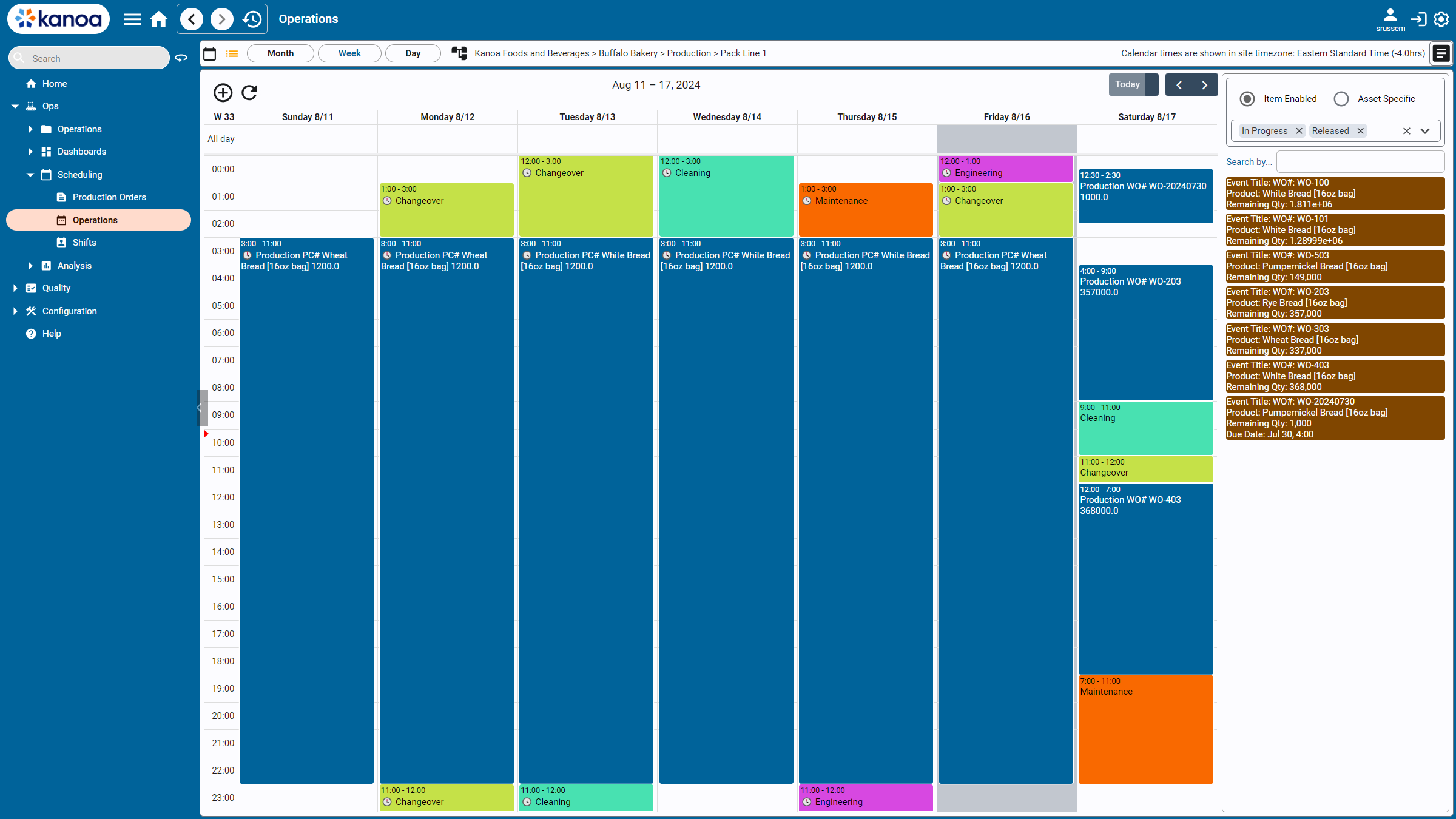

Production Scheduling

Set production schedules, drag-and-drop work orders, and manage non-production modes like Maintenance and Changeovers.

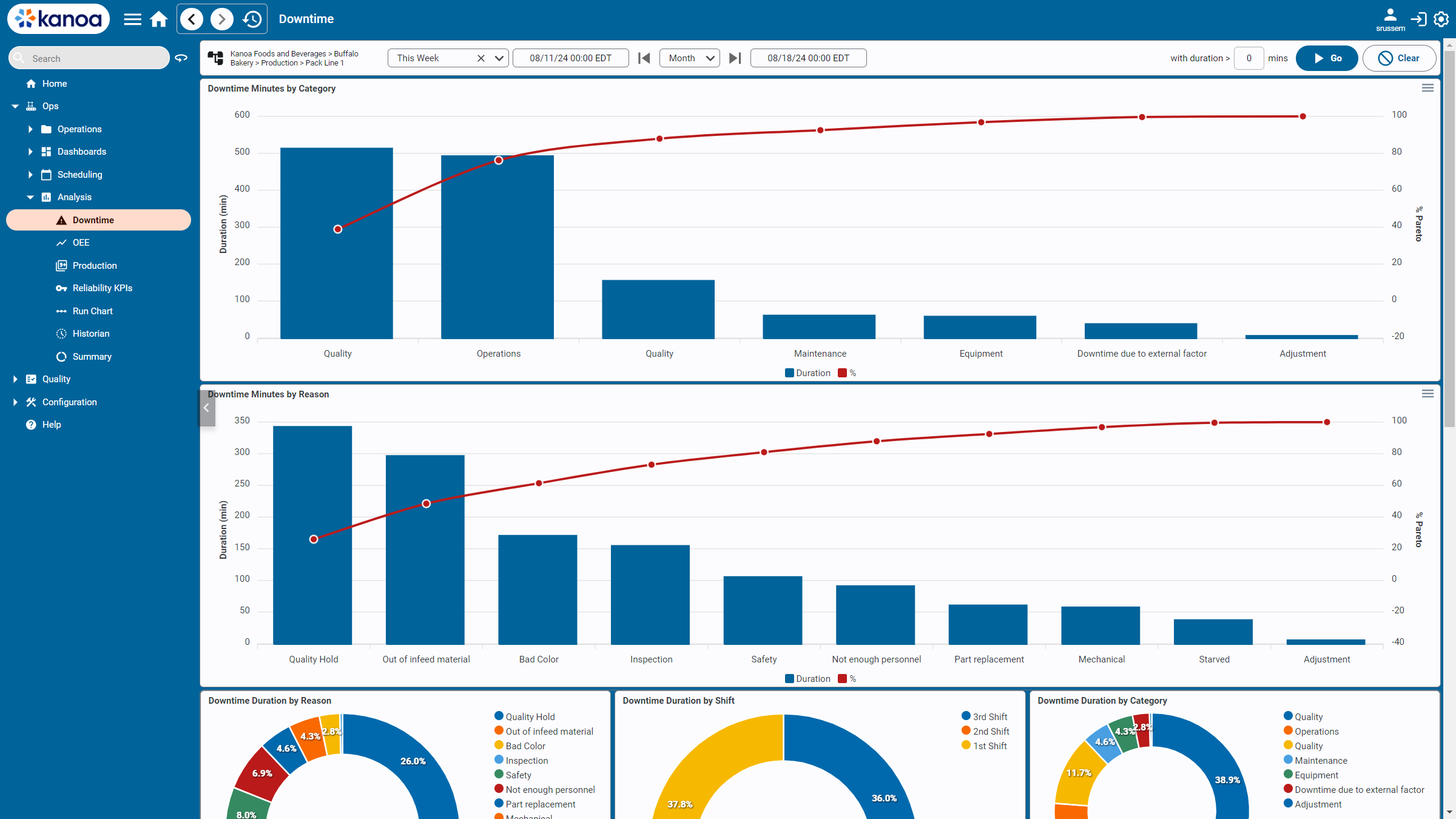

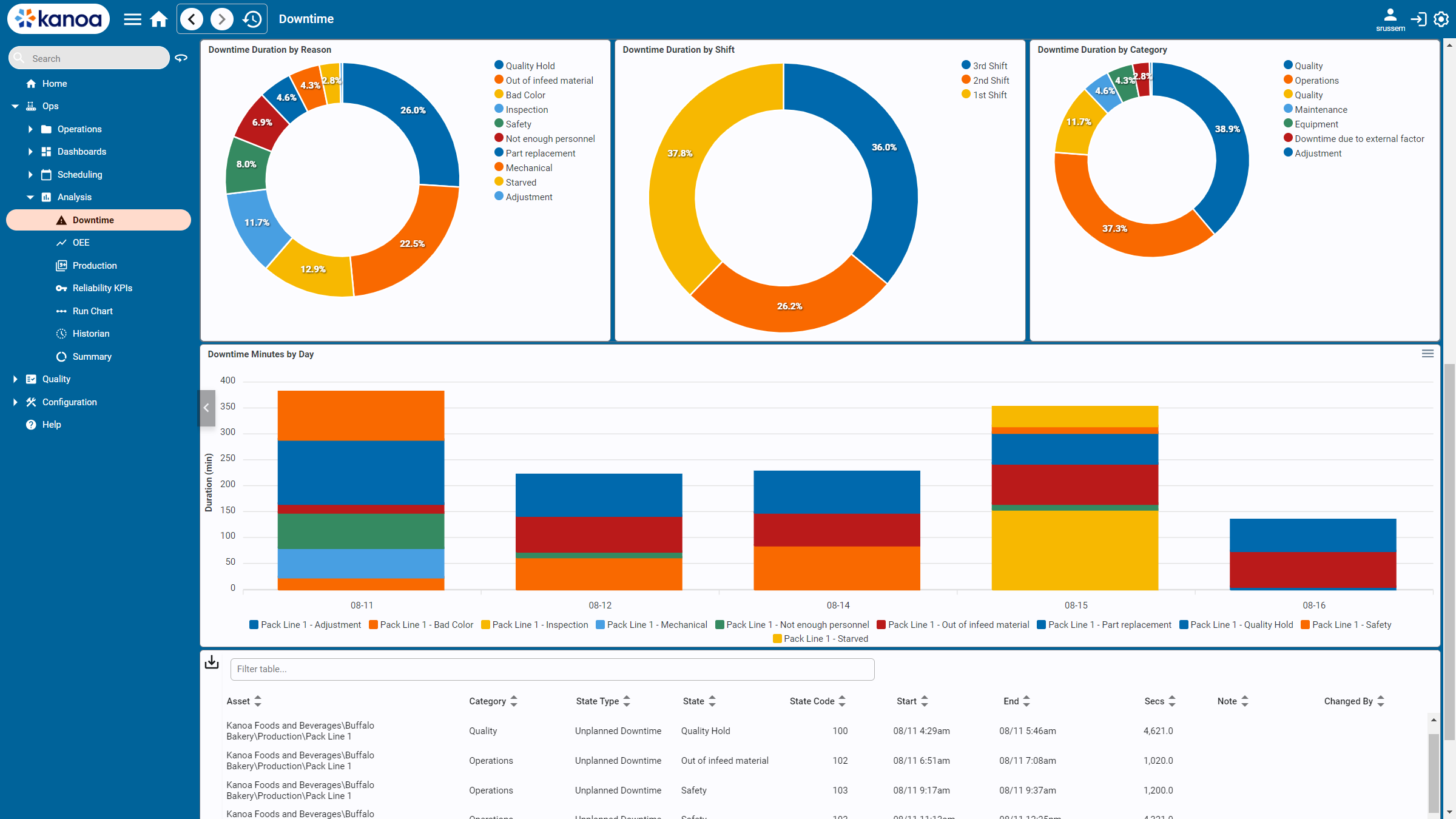

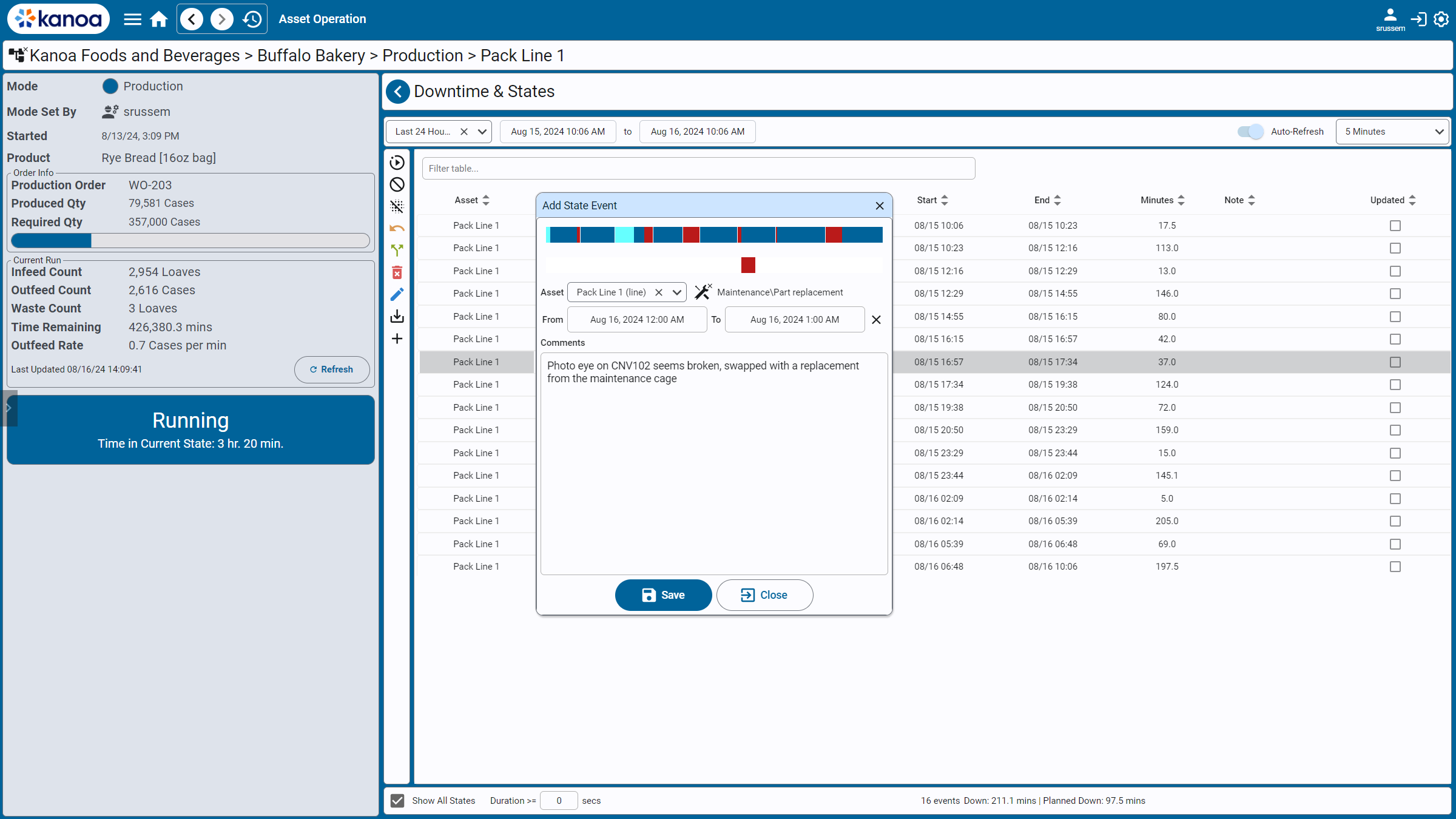

Downtime Analysis

Analyze unplanned downtime by asset, time, reason code, category, shift, and more.

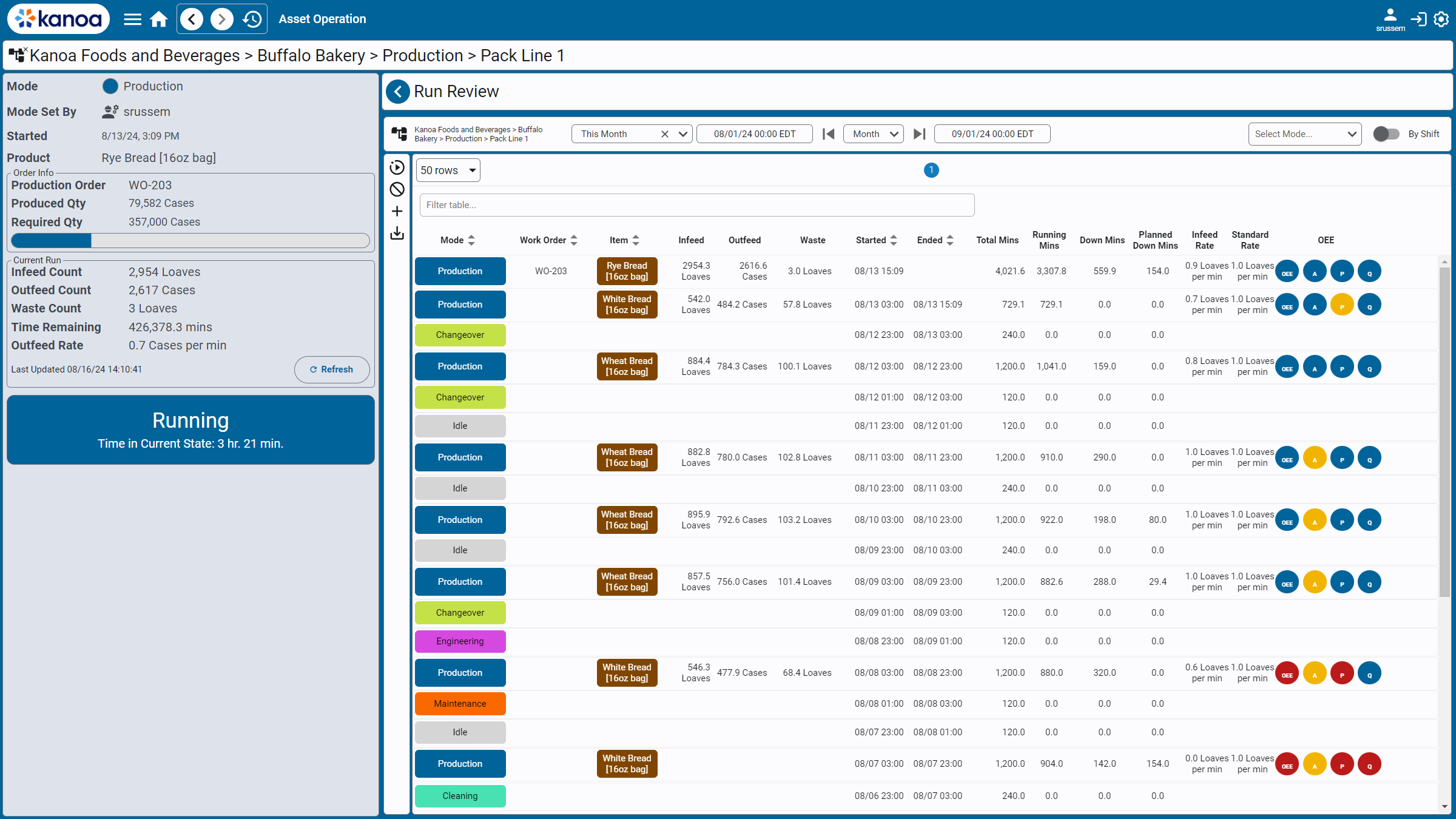

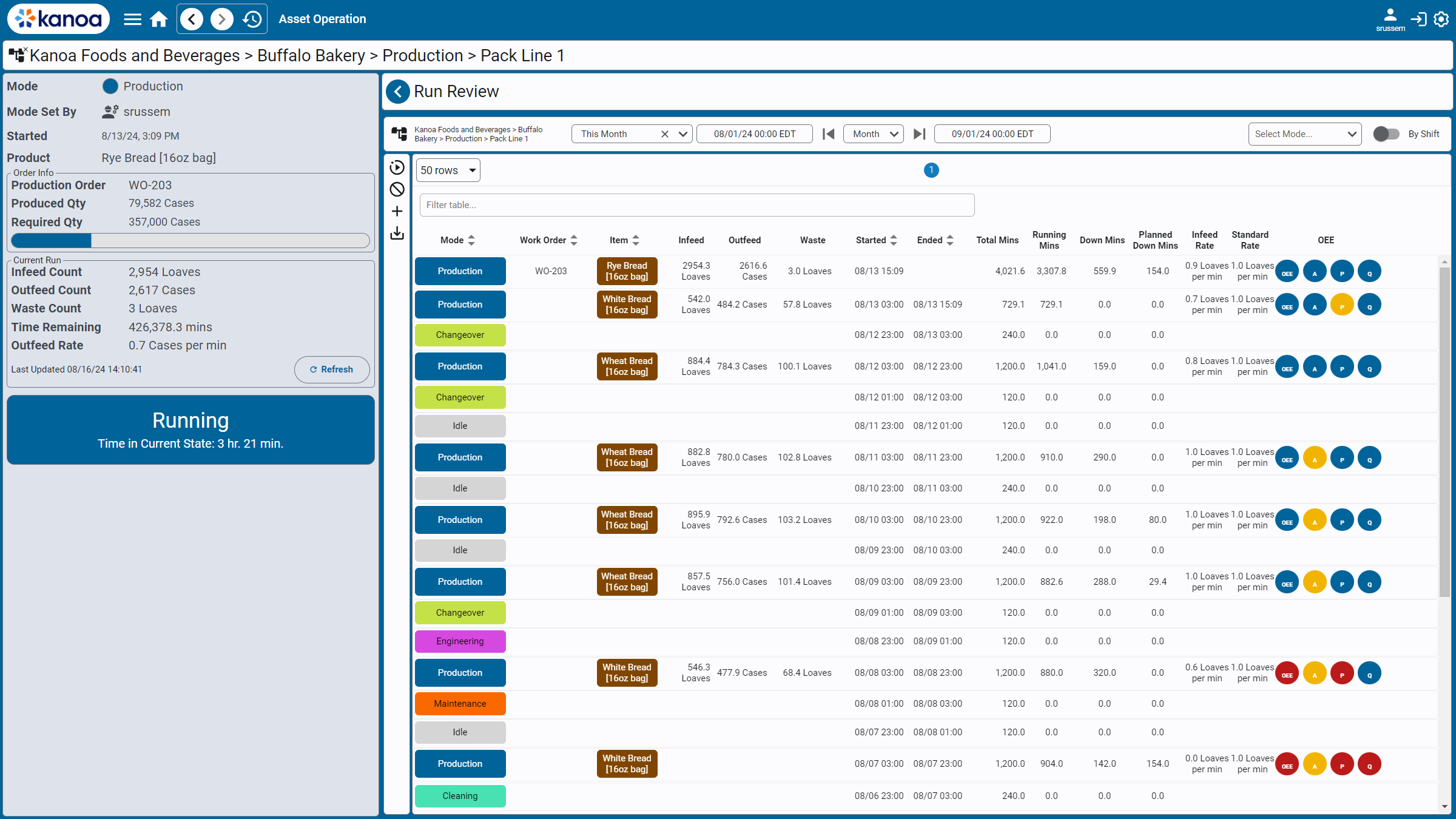

Run Review

View a every Production and Non-Production Event that occurred on the Asset, along with Production Counts and OEE KPI data.

Asset Cards

At-a-glance KPIs for all OEE Assets in an Area or Plant. Check out production status, work order progress, unplanned downtime, and OEE all in one place.

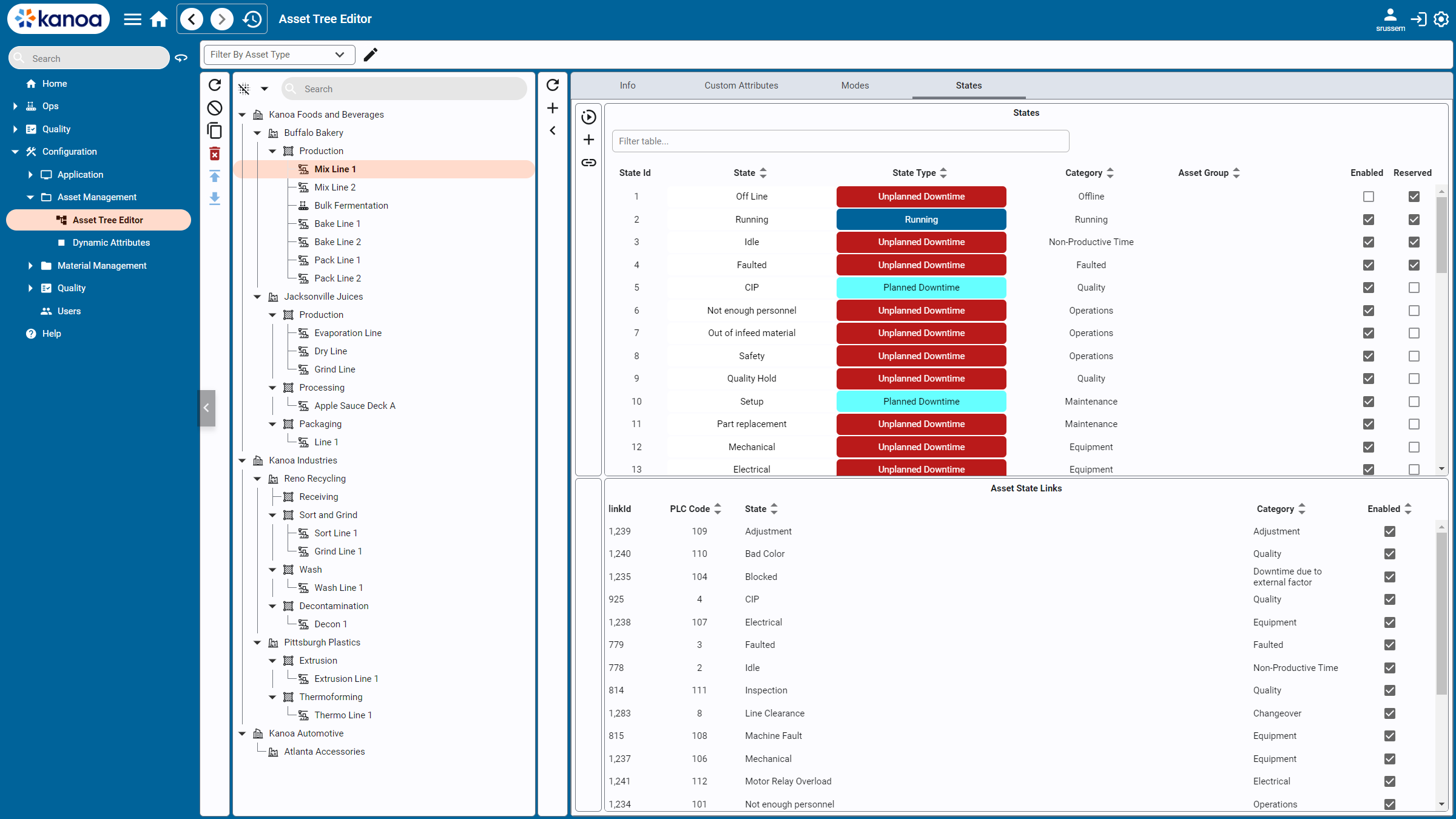

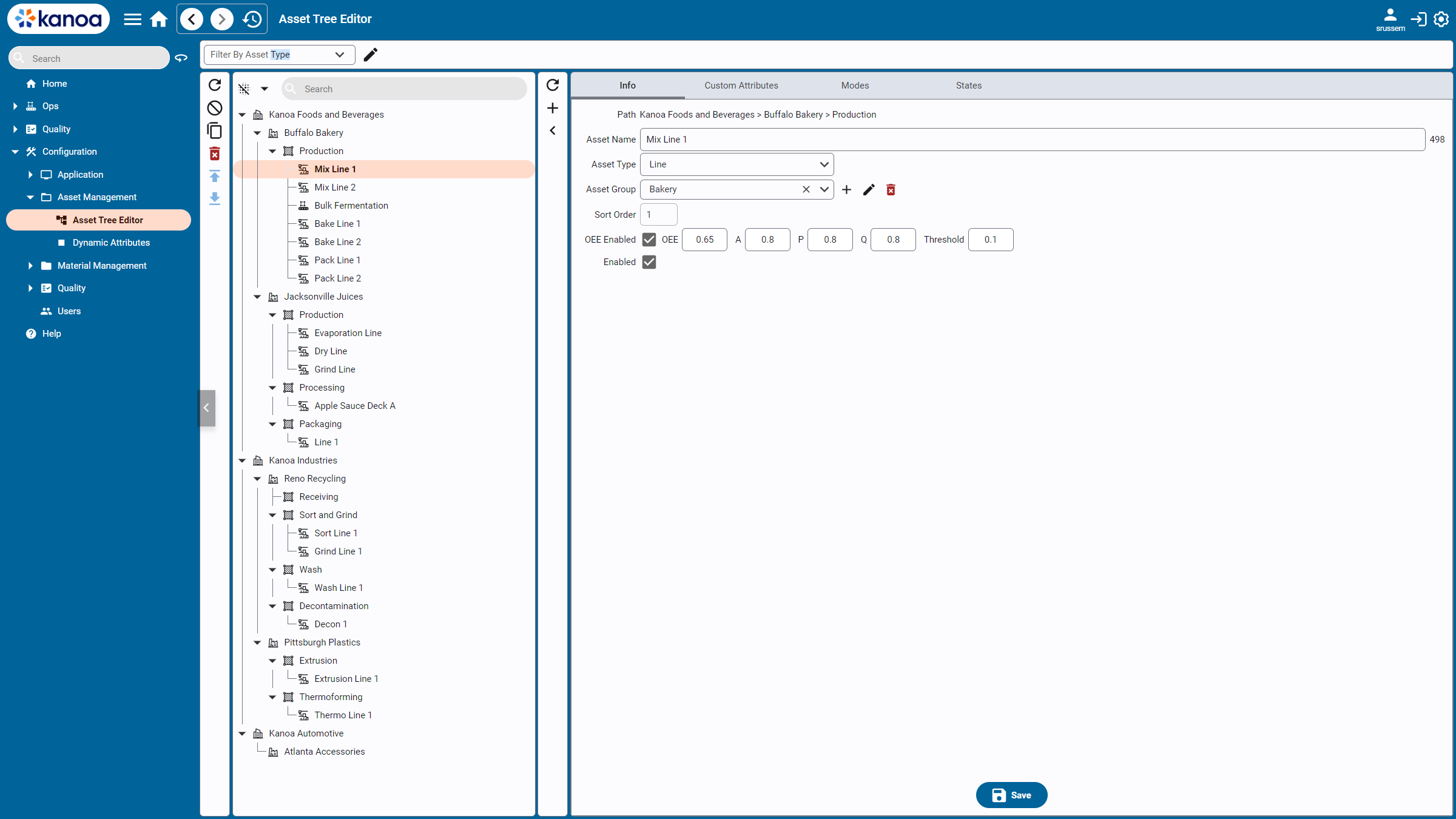

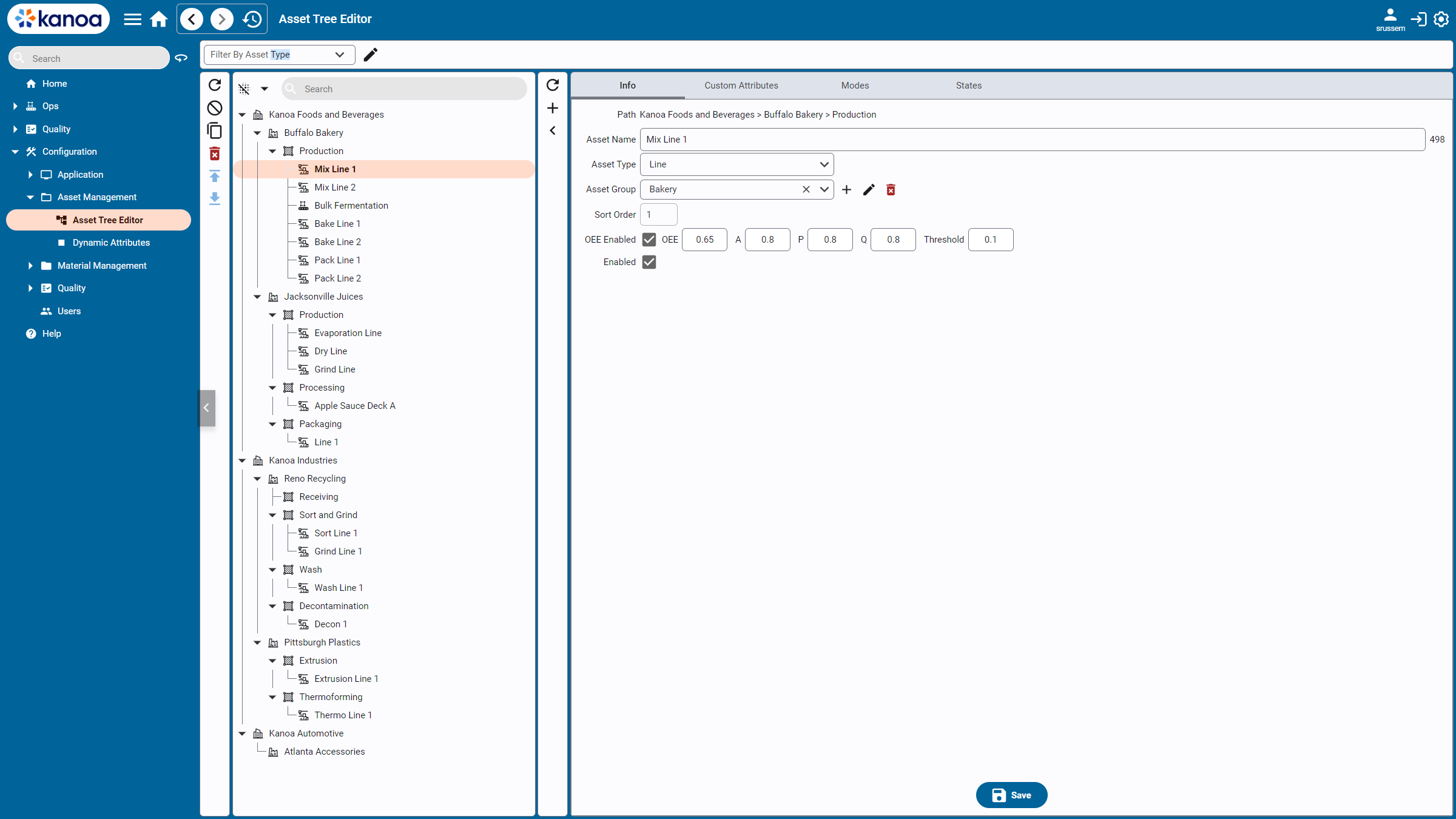

Configure Assets

Organize your assets using the ISA-95 Hierarchy (or not!). Set assets to be OEE Enabled to schedule work and track productivity.

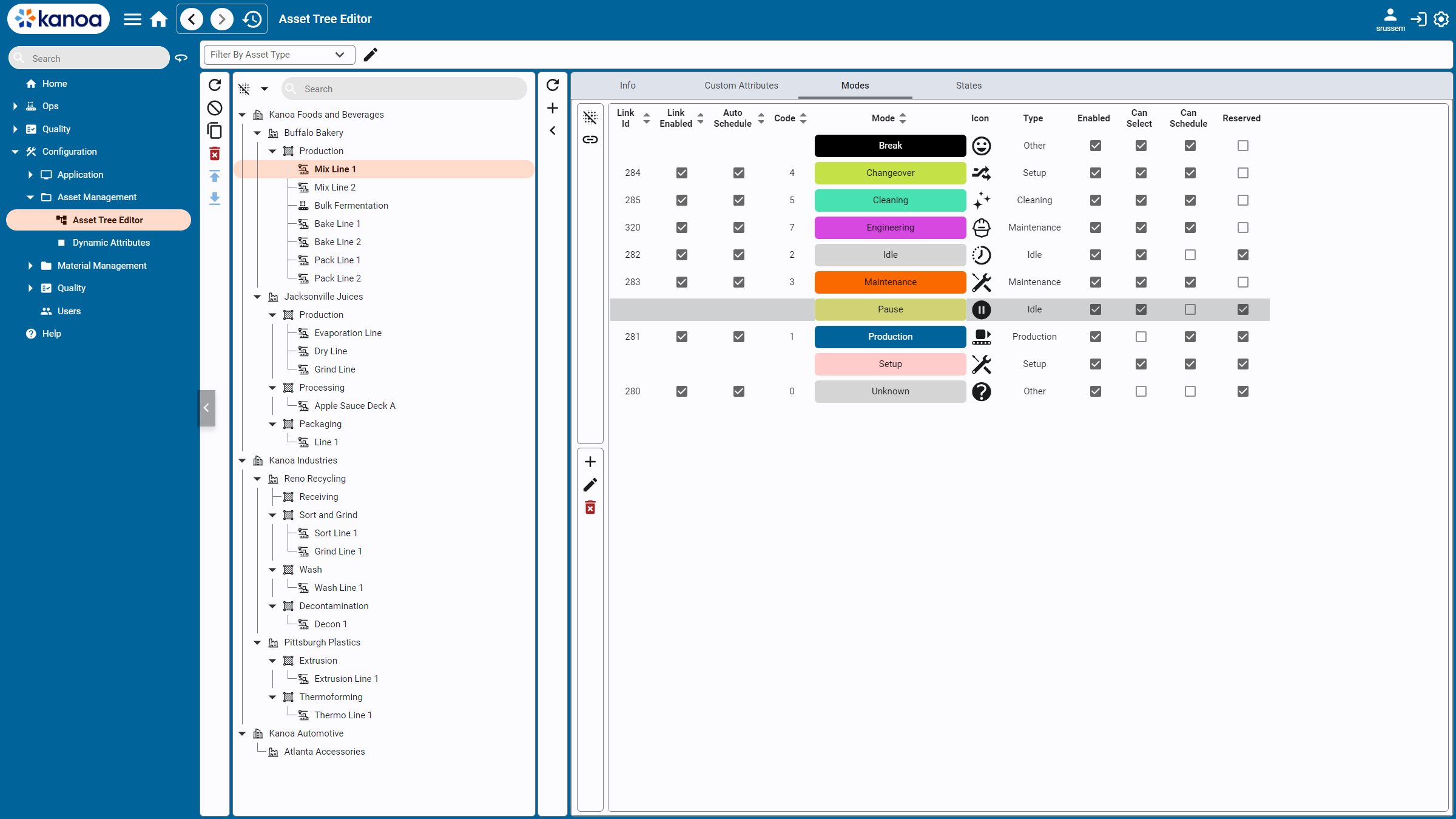

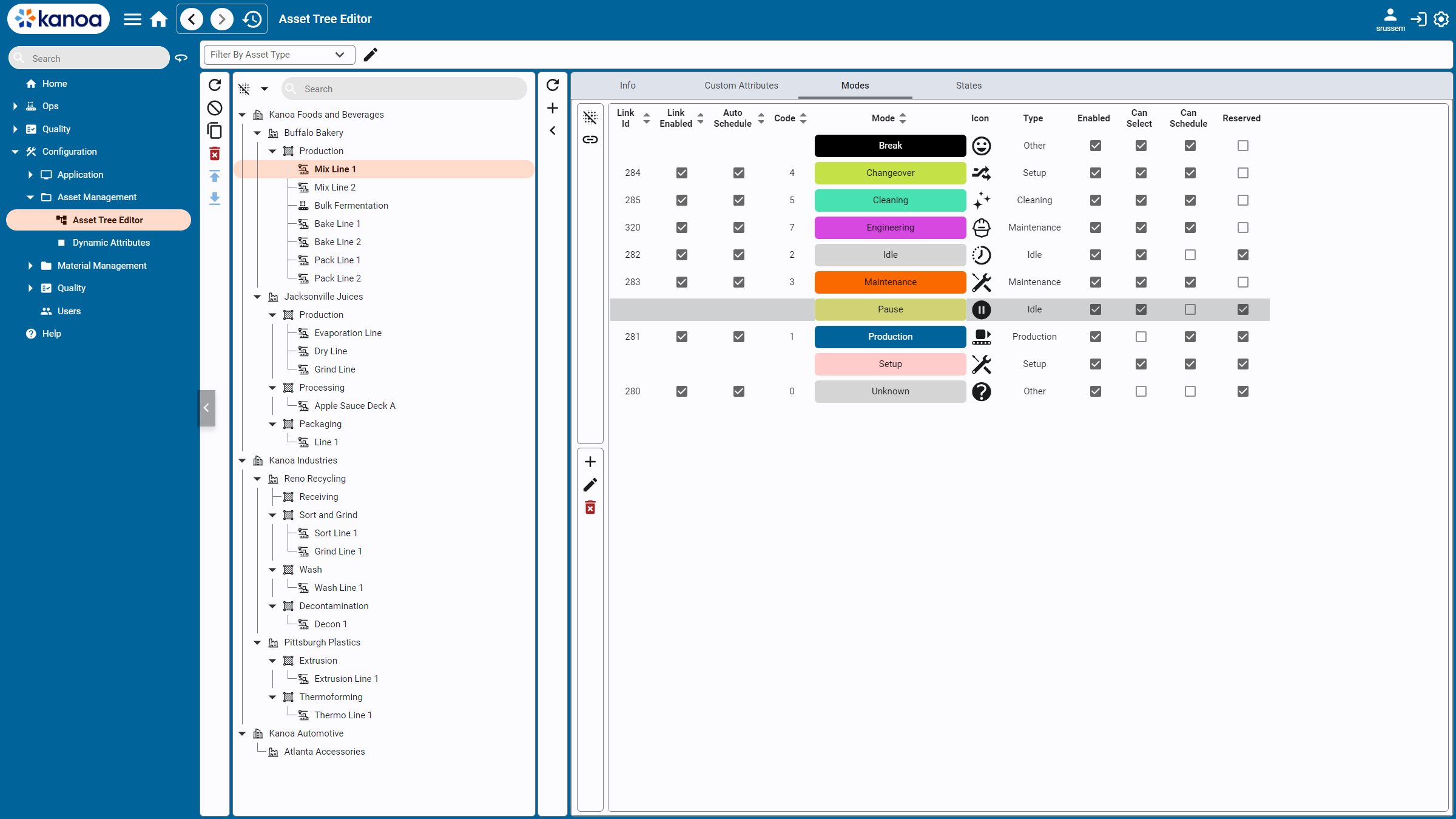

Configure Modes

Configure your list of Modes and link Modes to Assets. Modes describe what is intended to be happening on an asset.

Factory Data at your Fingertips

View the Production Status and KPIs for all of your key assets at-a-glance. Organize data by plant, area, line, and machine. Efficiency, downtime, work orders, and production progress all in one place.

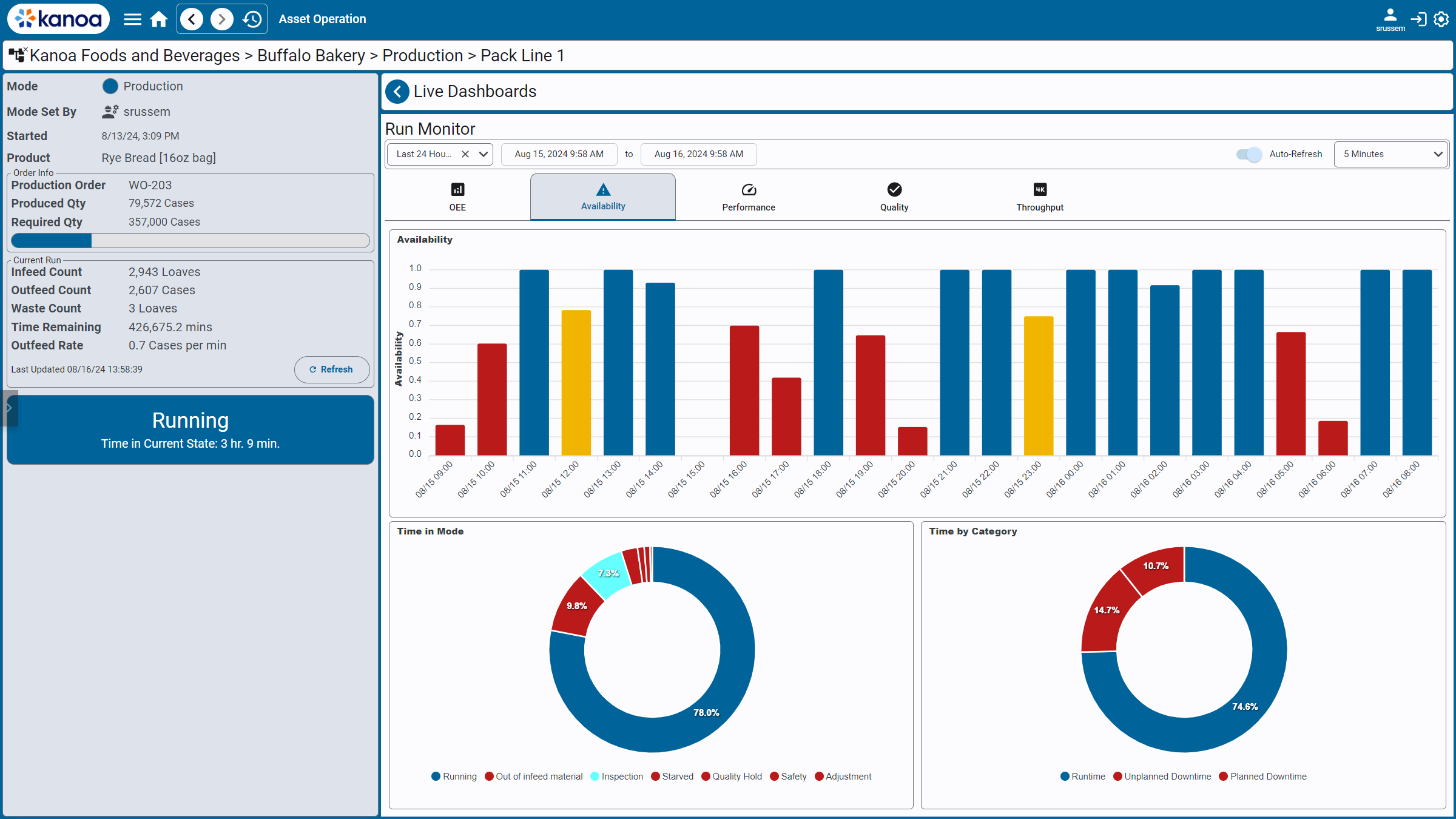

Intuitive Operator Terminals

Manage Lines and Machines from one easy to use Operator Interface. The Asset Operations screen is your one-stop-shop for Run Controls, Asset Status, Downtime Management, Manual Entry, and Live Dashboards.

Master Production Scheduling

Create and optimize production and shift schedules for your factory. Drag-and-drop work orders to assign work to assets. Schedule and measure non-productive time like Changeovers and Cleaning. Manage shift schedules by area or by asset, including support for complex shift rotation patterns.

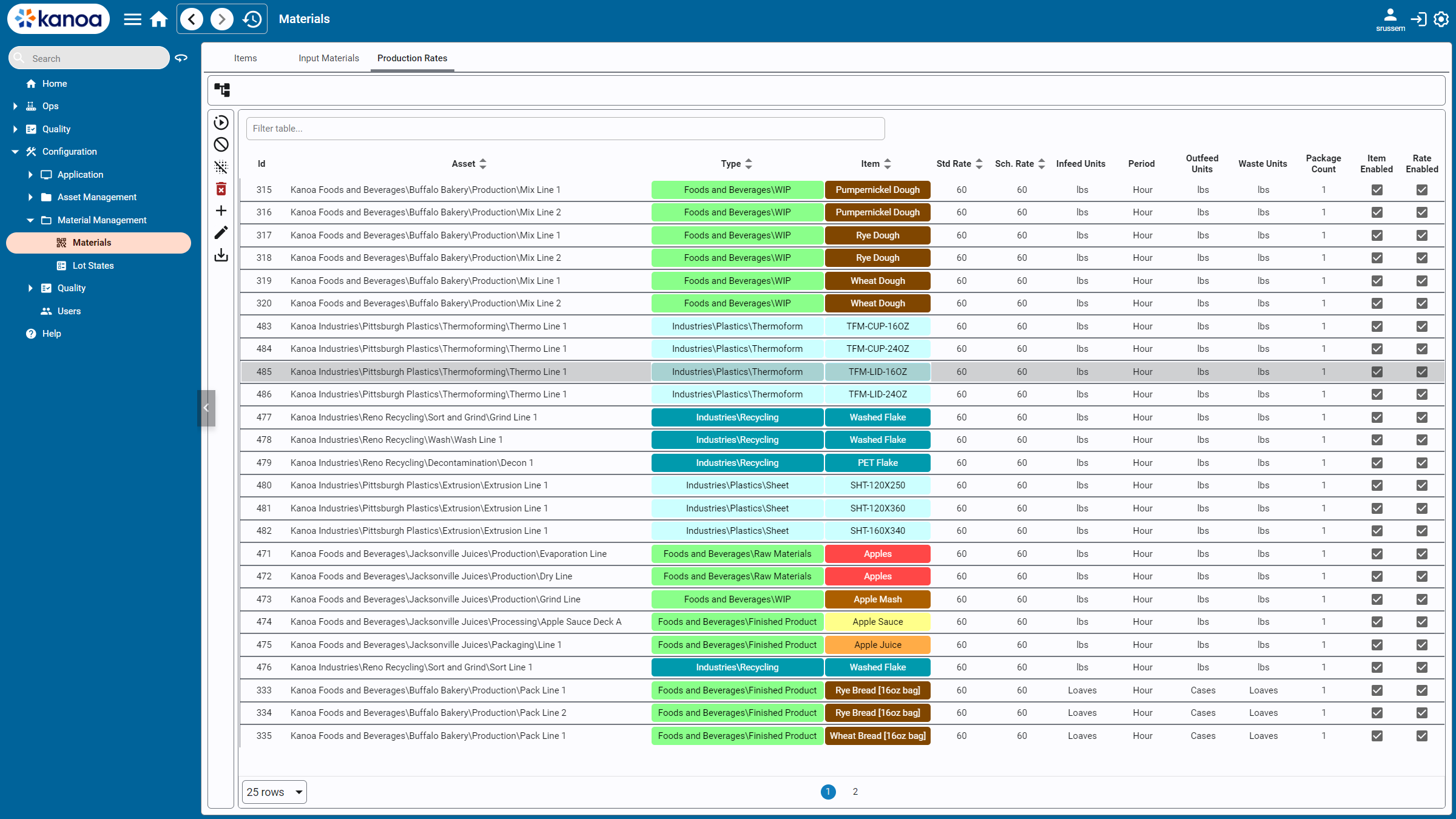

Configure, Don't Code

Design and configure your factory's new MES with the Kanoa APP's built-in tools. Create your factory's asset hierarchy, enable assets for OEE and production tracking, assign modes and states, create materials, assign production rates, and more! Kanoa Ops only needs 3 tags for complete OEE KPIs.