QUALITY FORMS AND SPC

Kanoa Quality

Design and dispatch quality and compliance forms for your factory. Analyze quality data with built-in Statistical Process Control (SPC), Histograms, and more! Create form dispatching rules and track compliance. Create a culture of Quality that's easy to implement and to overlook.

Kanoa Quality is an add-on solution and requires Kanoa Ops.

Quality management that fits production reality

Kanoa Quality enables teams to standardize inspection workflows, capture measurements and outcomes, and support compliance without disconnected spreadsheets or custom projects.

Design your Quality Forms

Create the forms and check sheets required for your factory, process, and compliance needs.

Get Paper off the Factory Floor

Replace all your paper runners and check sheets with digital forms to reduce mistakes and deliver real-time feedback

Dispatching and Compliance

Issue forms on a schedule or by production event, then track completion times and make sure all your checks are getting done.

Kanoa Quality Features

Configure, Don't Code

Analytics & SPC

Mobile Ready

Manual & Auto Data Collection

Scheduling & Dispatching

Designed for Operators

Signoff & Approval Management

Image Capture

Attach images from your phone, tablet, or desktop to Quality checks

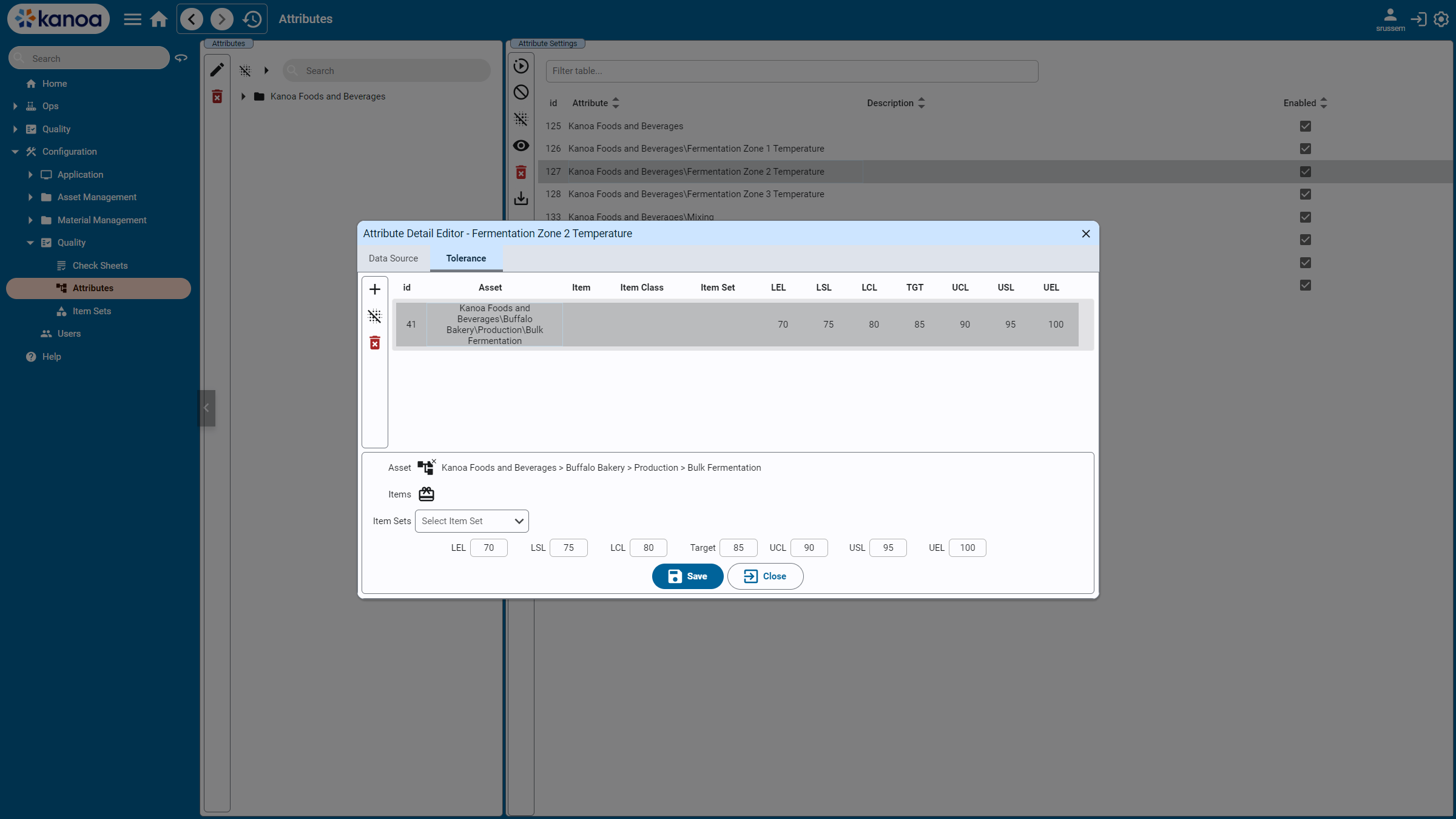

Tolerance Management

Built on Ops

Kanoa Quality relies on Kanoa Ops for work order execution context and consistent production modeling—so quality records remain connected to the real conditions and events that produced them.

Let's take a tour

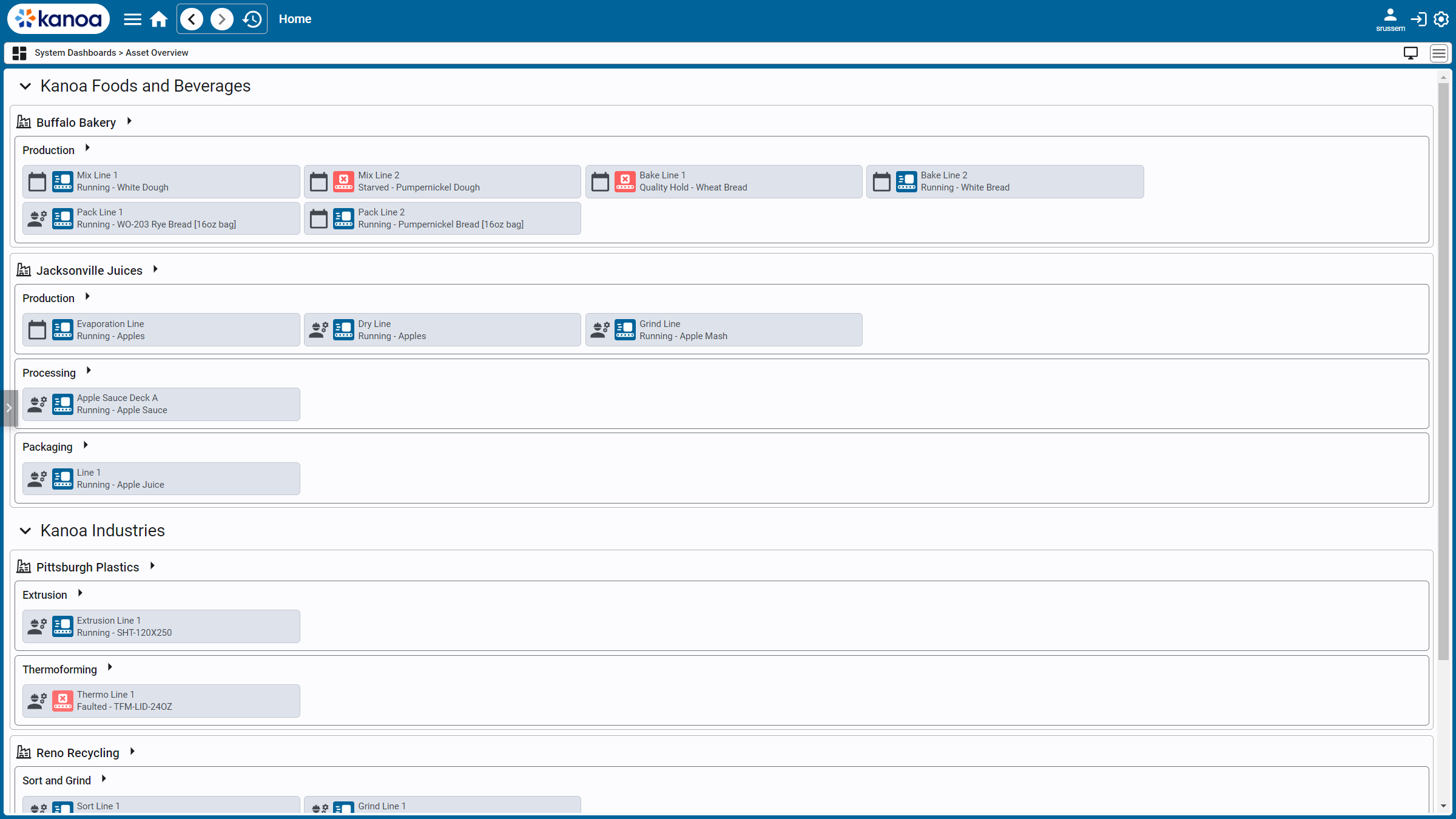

Asset Overview

Your entire Enterprise and Factory, all in one place. See what's running on each asset and its current production state.

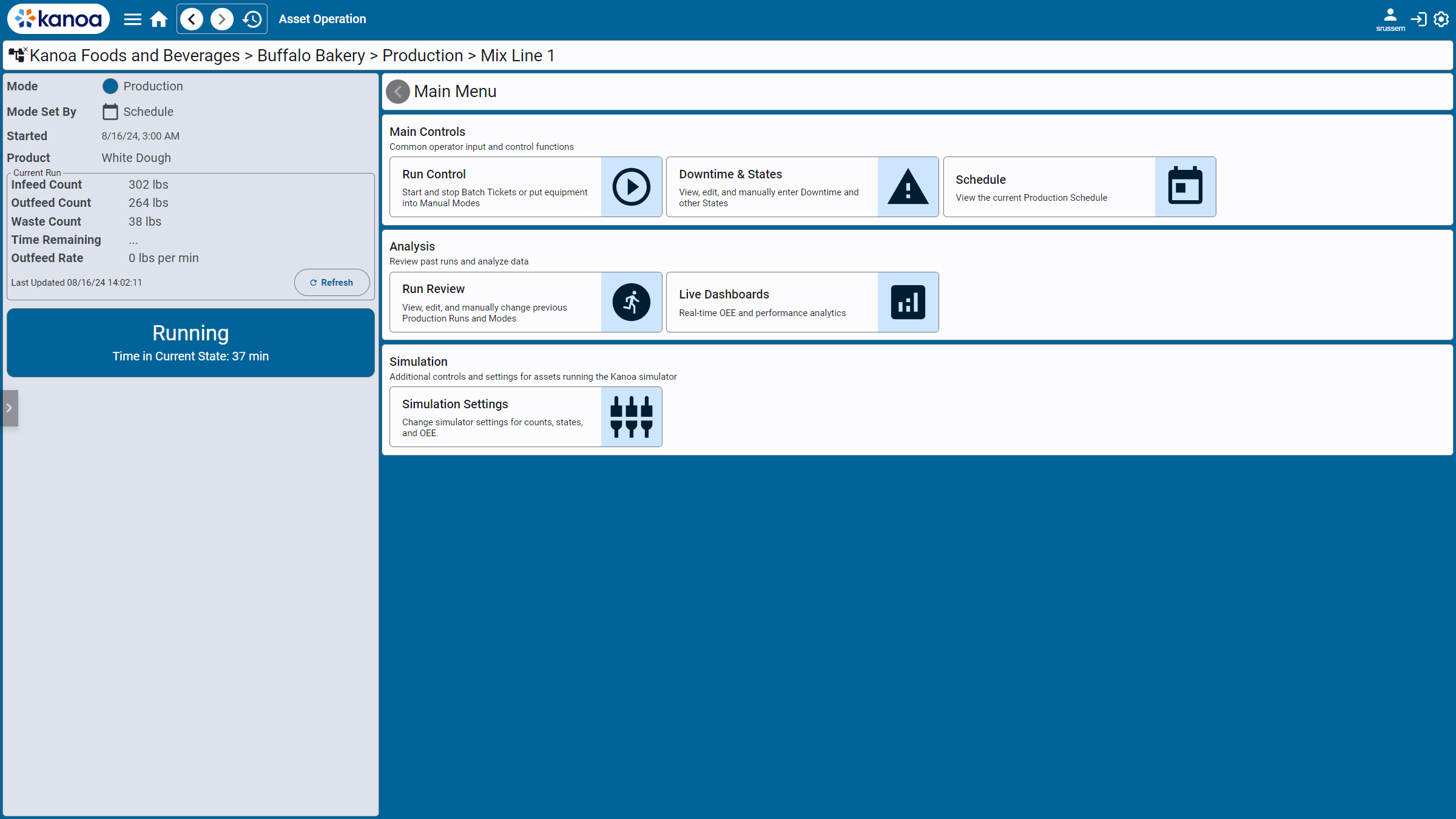

Asset Operations Home

Your one-stop-shop for all your daily Asset Operation needs. Manage and control production assets from this one simple screen.

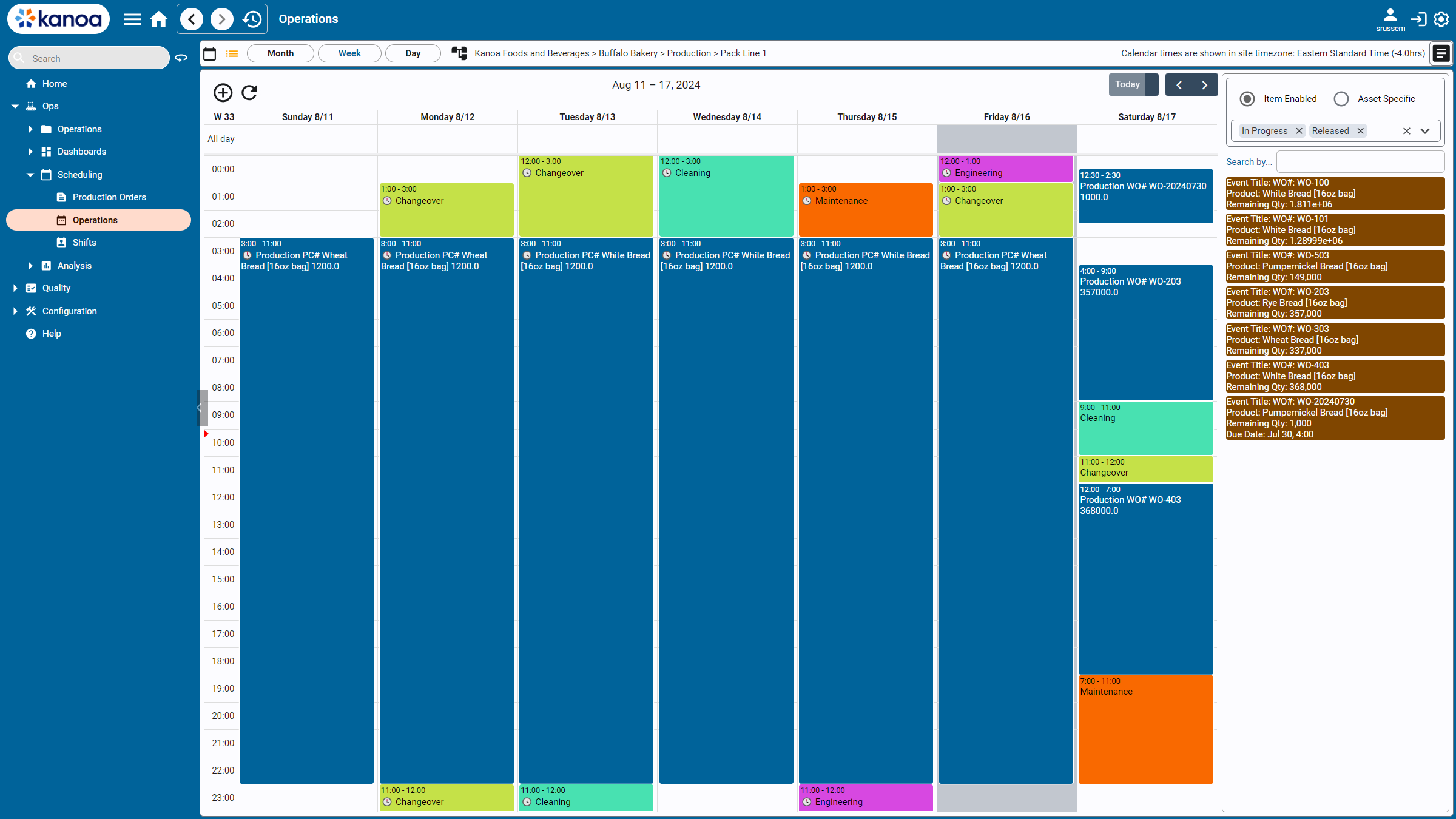

Production Scheduling

Set production schedules, drag-and-drop work orders, and manage non-production modes like Maintenance and Changeovers.

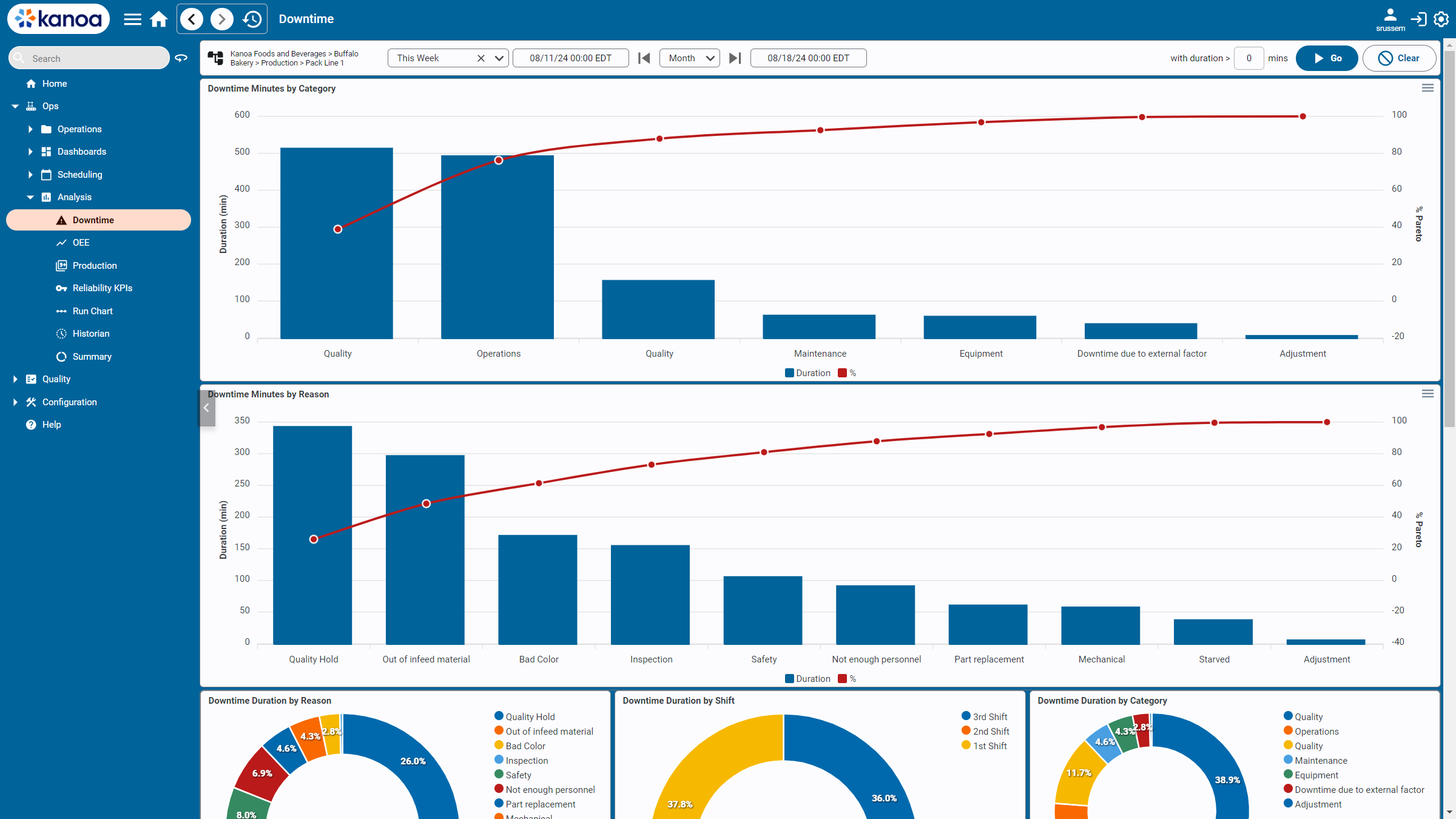

Downtime Analysis

Analyze unplanned downtime by asset, time, reason code, category, shift, and more.

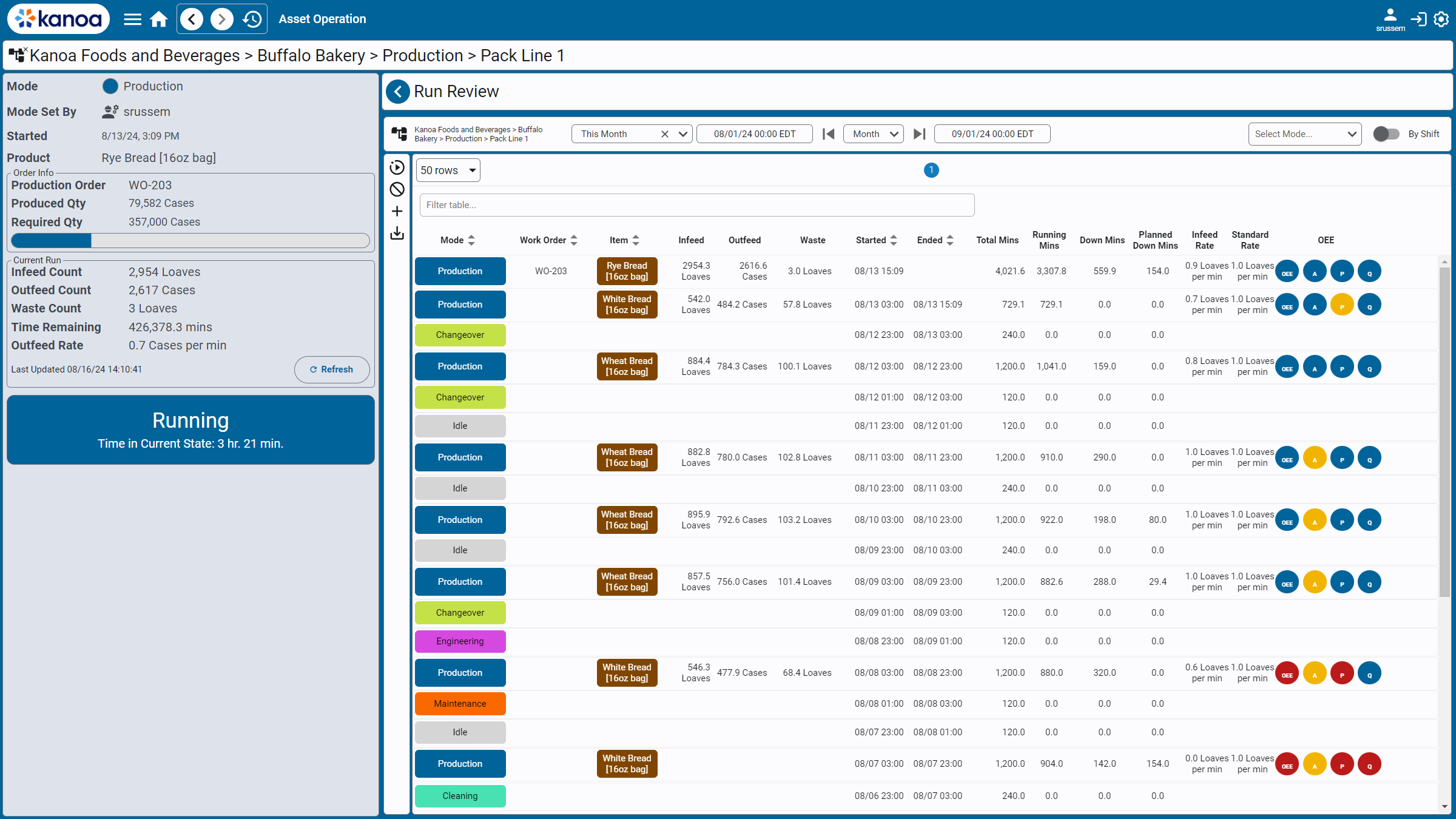

Run Review

View a every Production and Non-Production Event that occurred on the Asset, along with Production Counts and OEE KPI data.

Asset Cards

At-a-glance KPIs for all OEE Assets in an Area or Plant. Check out production status, work order progress, unplanned downtime, and OEE all in one place.

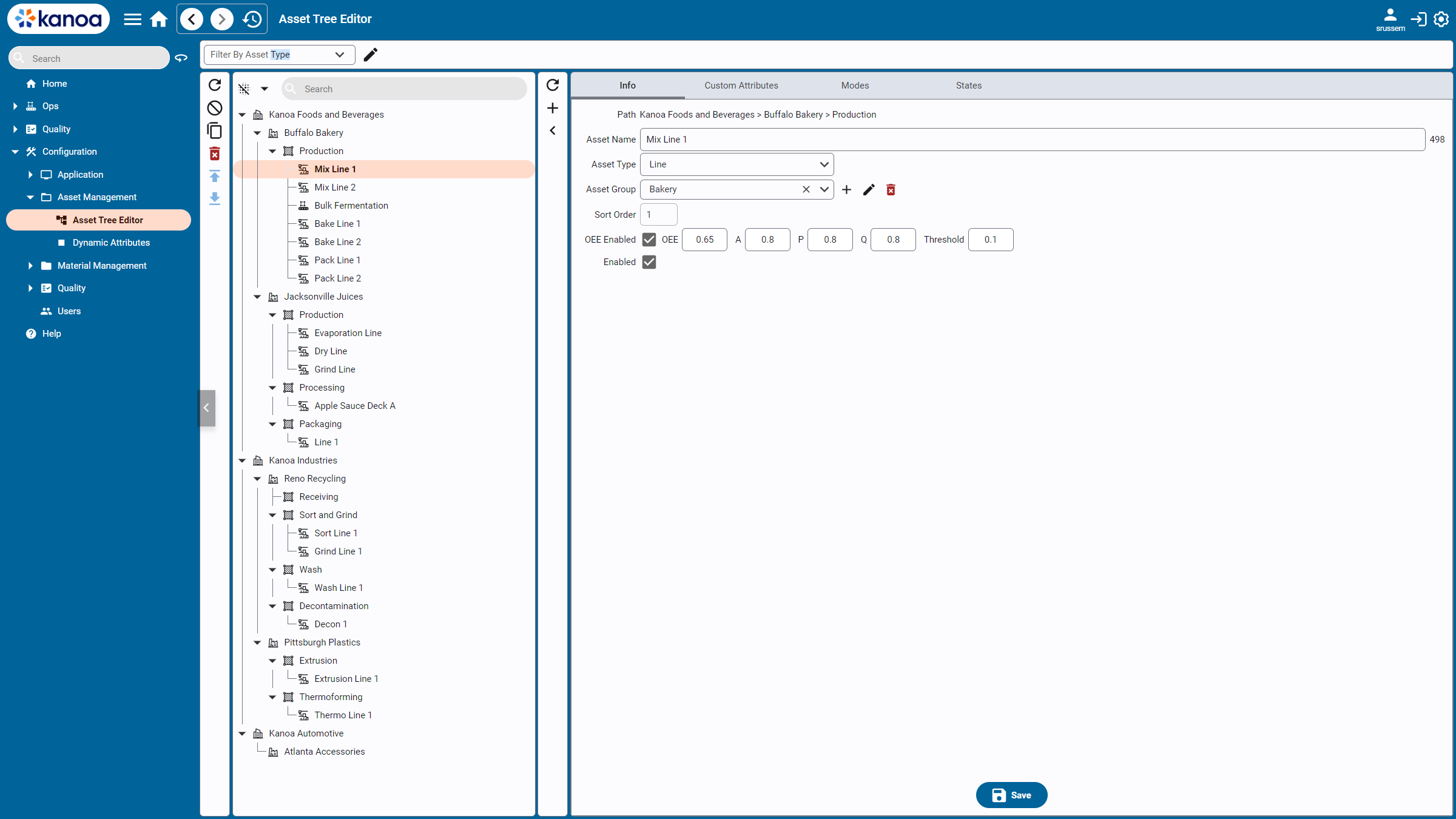

Configure Assets

Organize your assets using the ISA-95 Hierarchy (or not!). Set assets to be OEE Enabled to schedule work and track productivity.

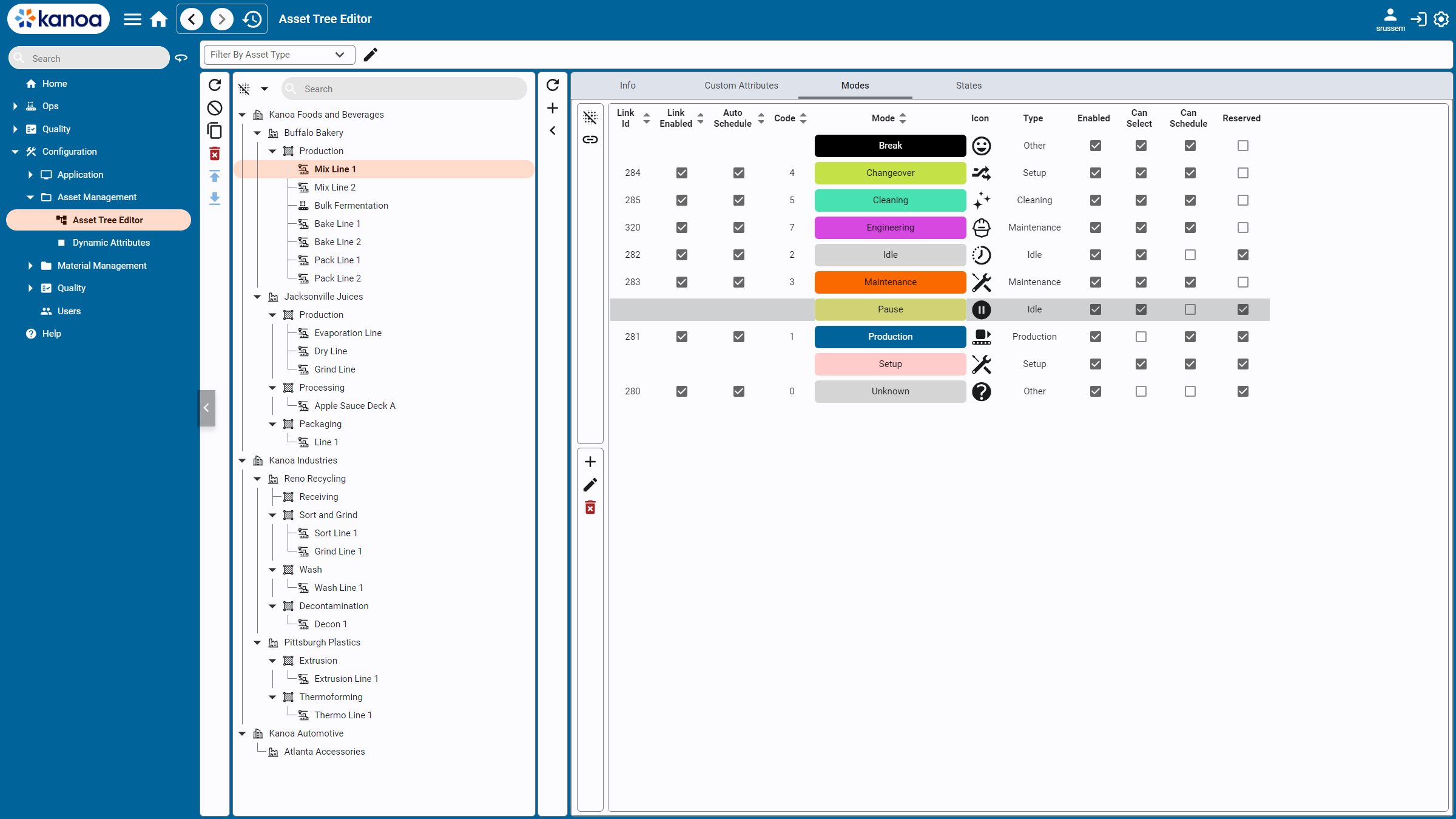

Configure Modes

Configure your list of Modes and link Modes to Assets. Modes describe what is intended to be happening on an asset.

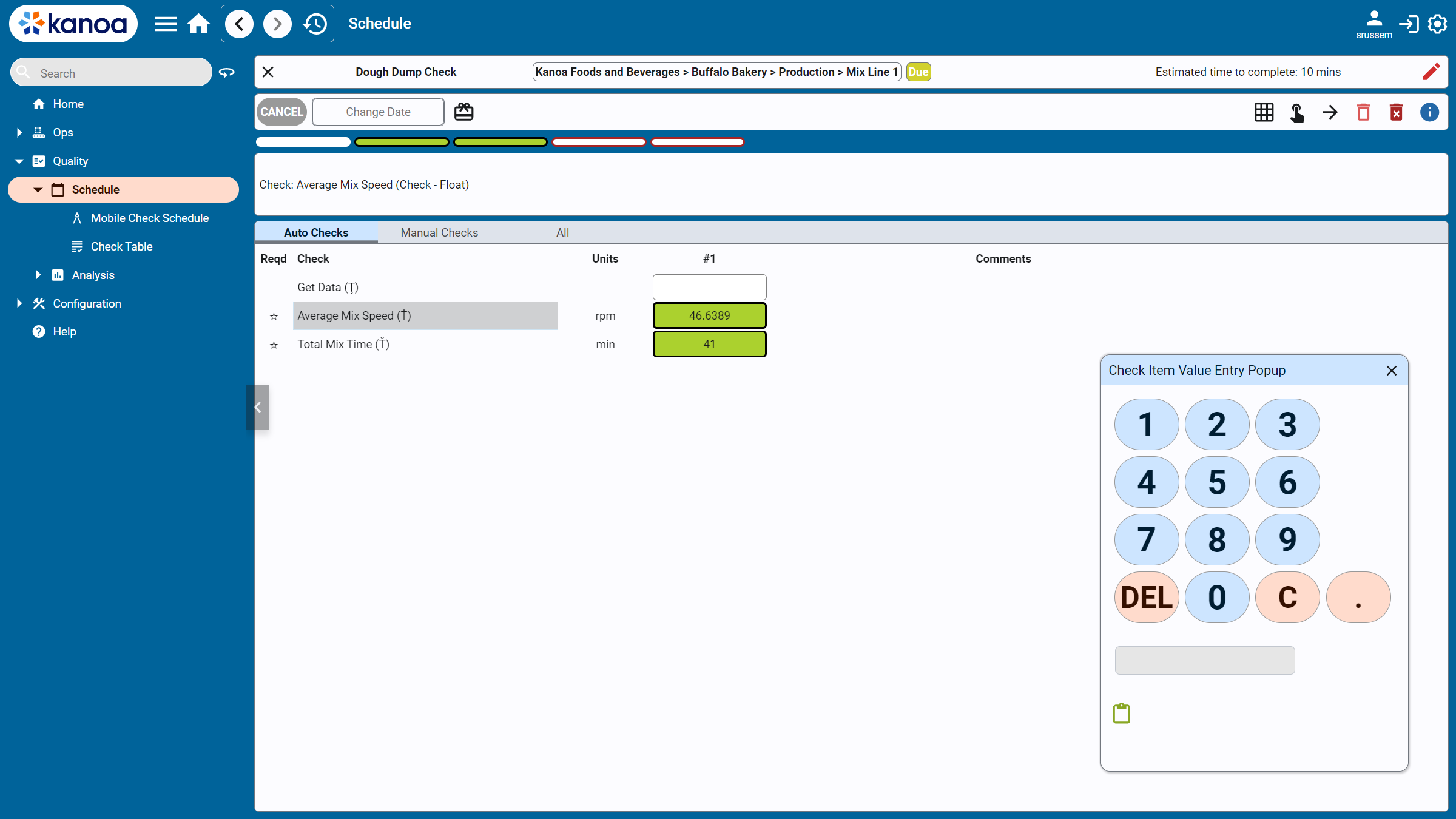

Forms & Check Sheets

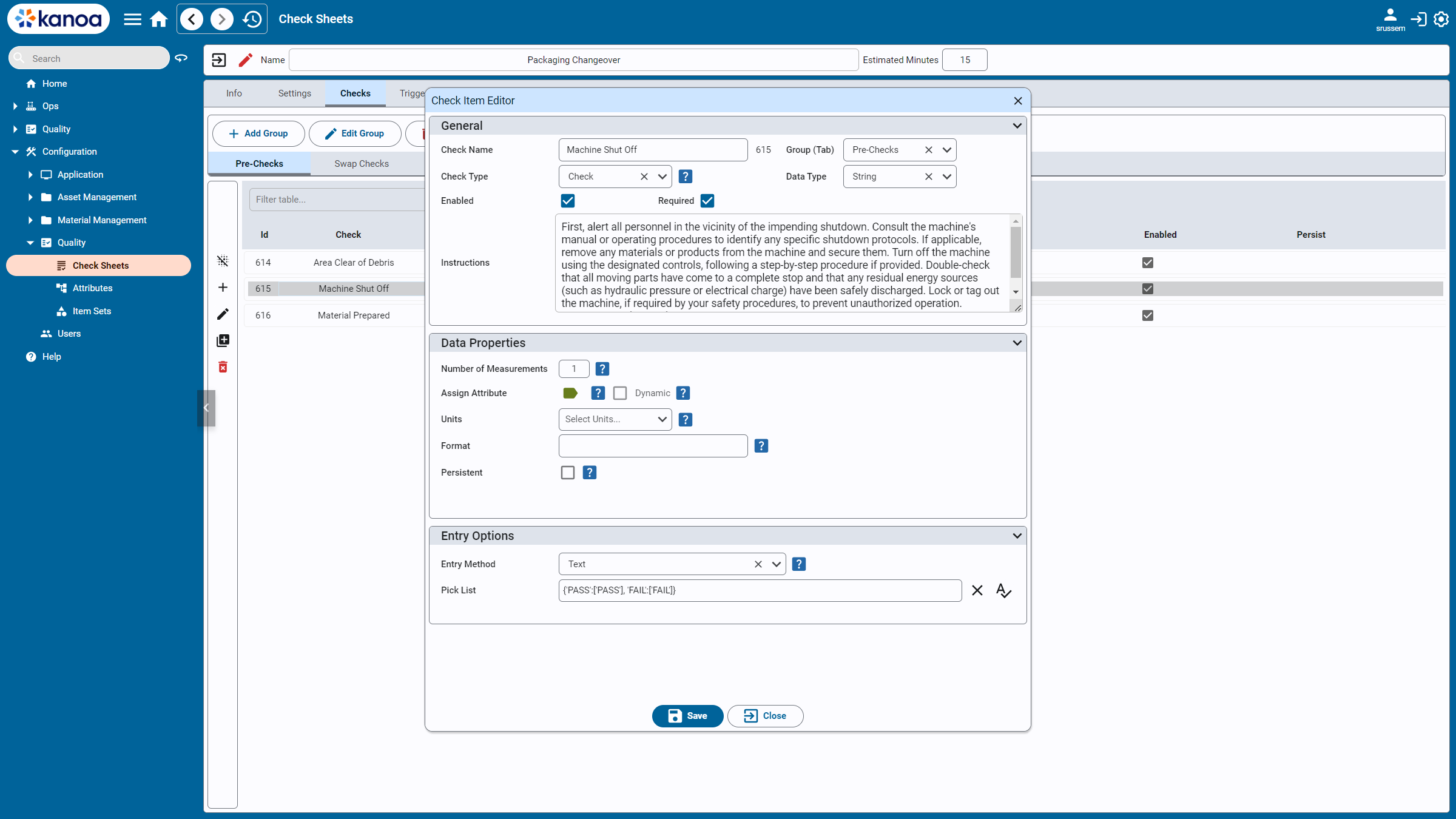

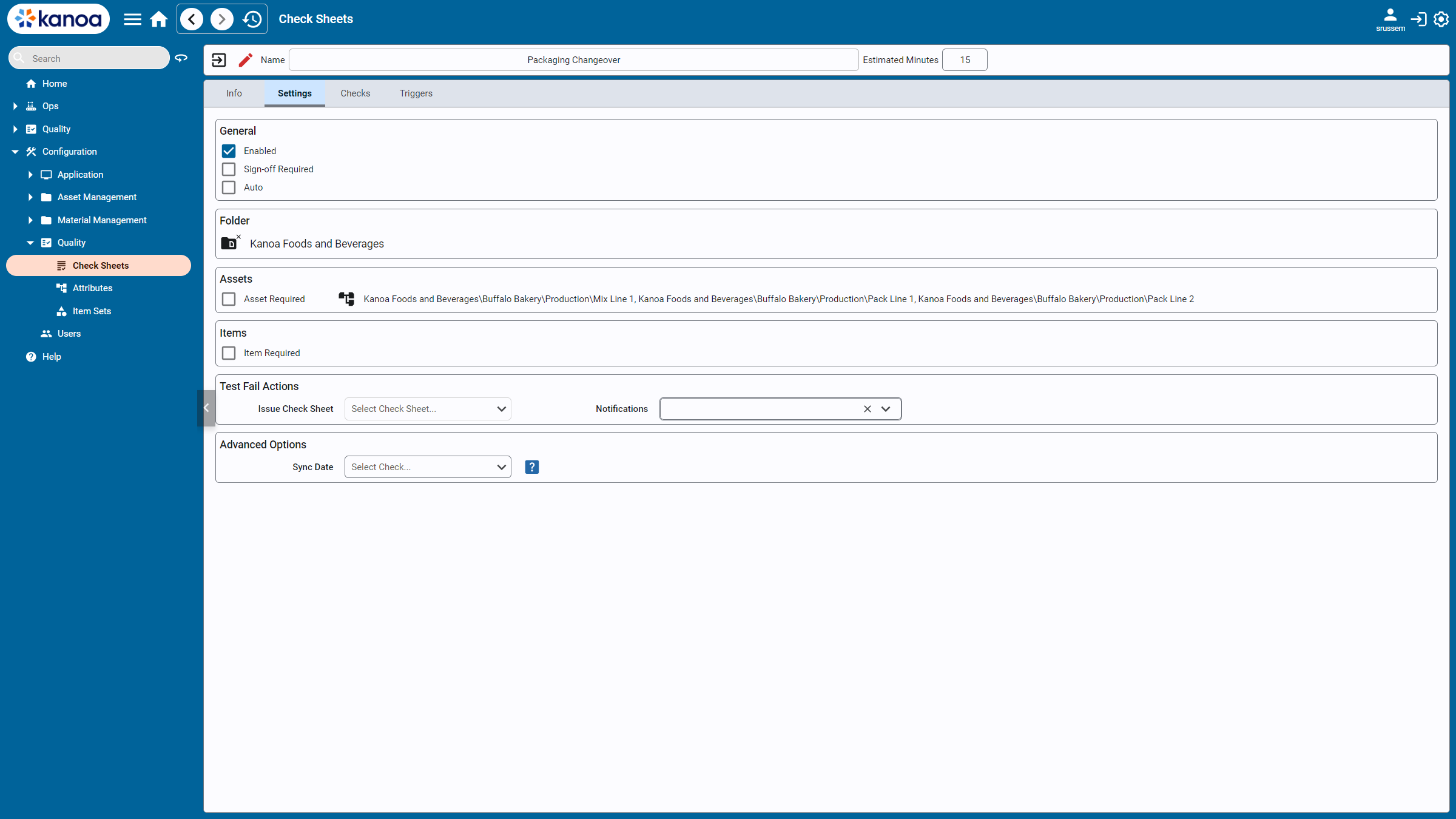

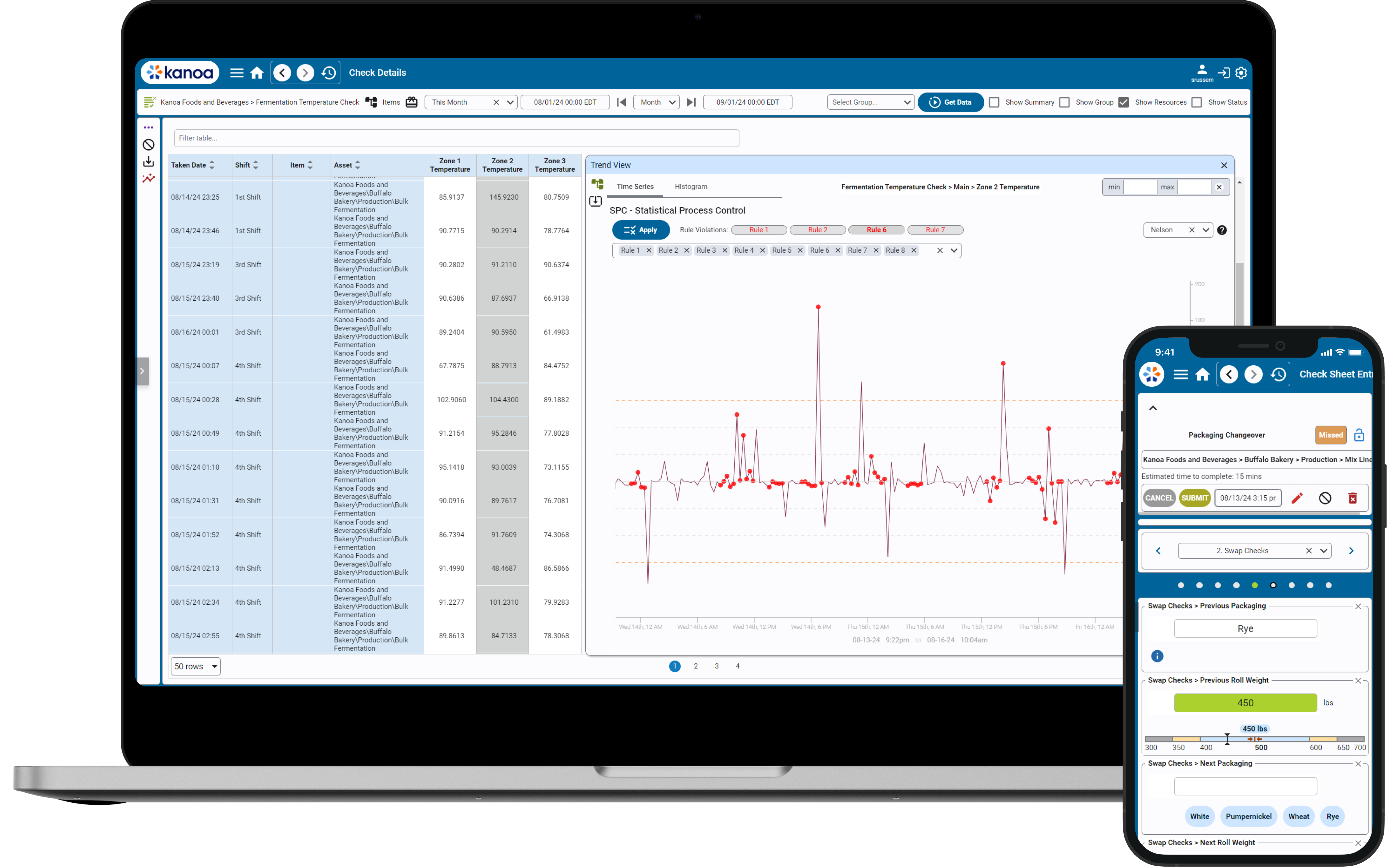

The Check Sheet is the focal point of Kanoa Quality. Think of each Check Sheet as replacing a paper form. A Check Sheet defines all of the data required to complete a quality check or process along with engineering tolerances, operator instructions, associated assets and items, and approval requirements.

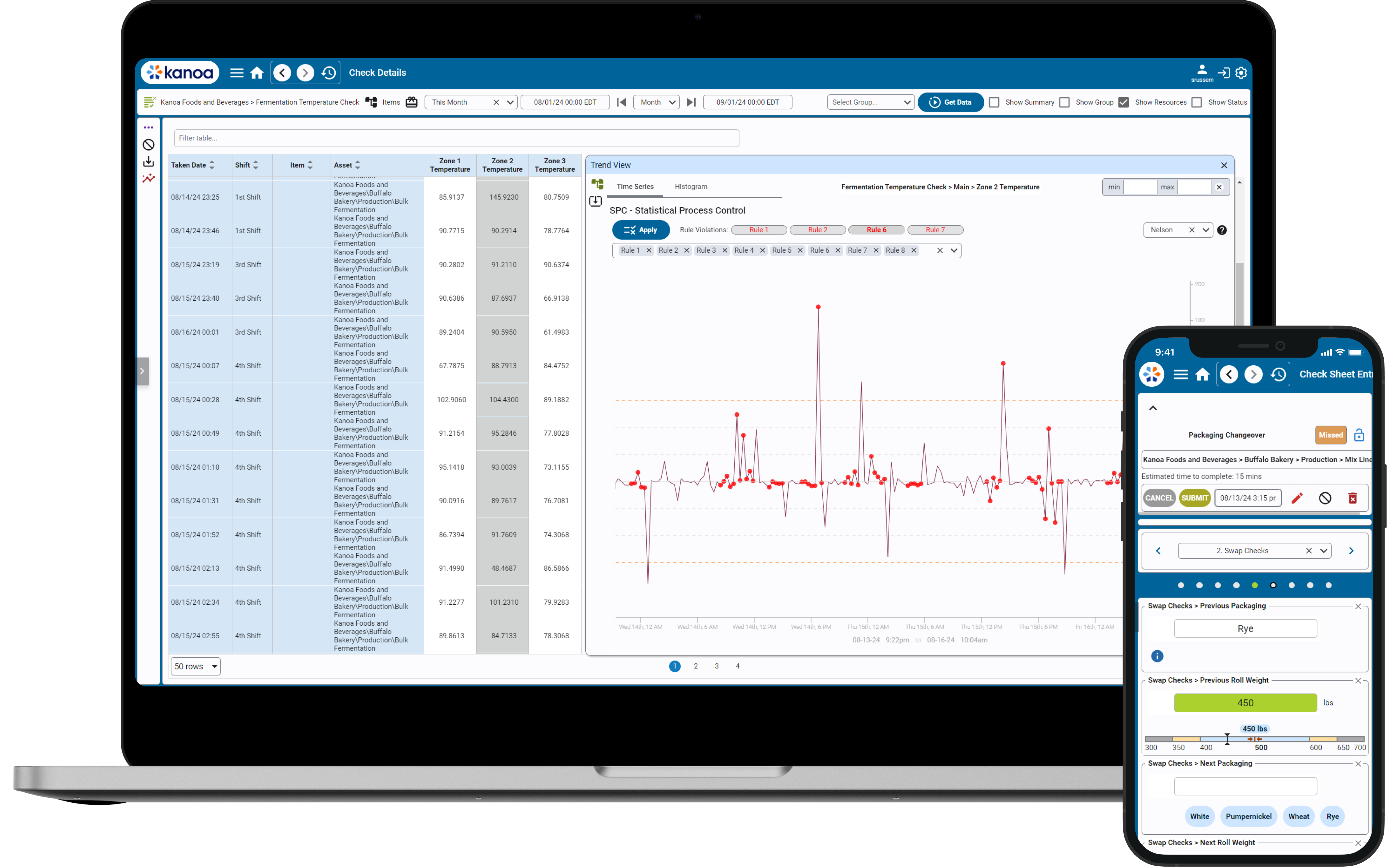

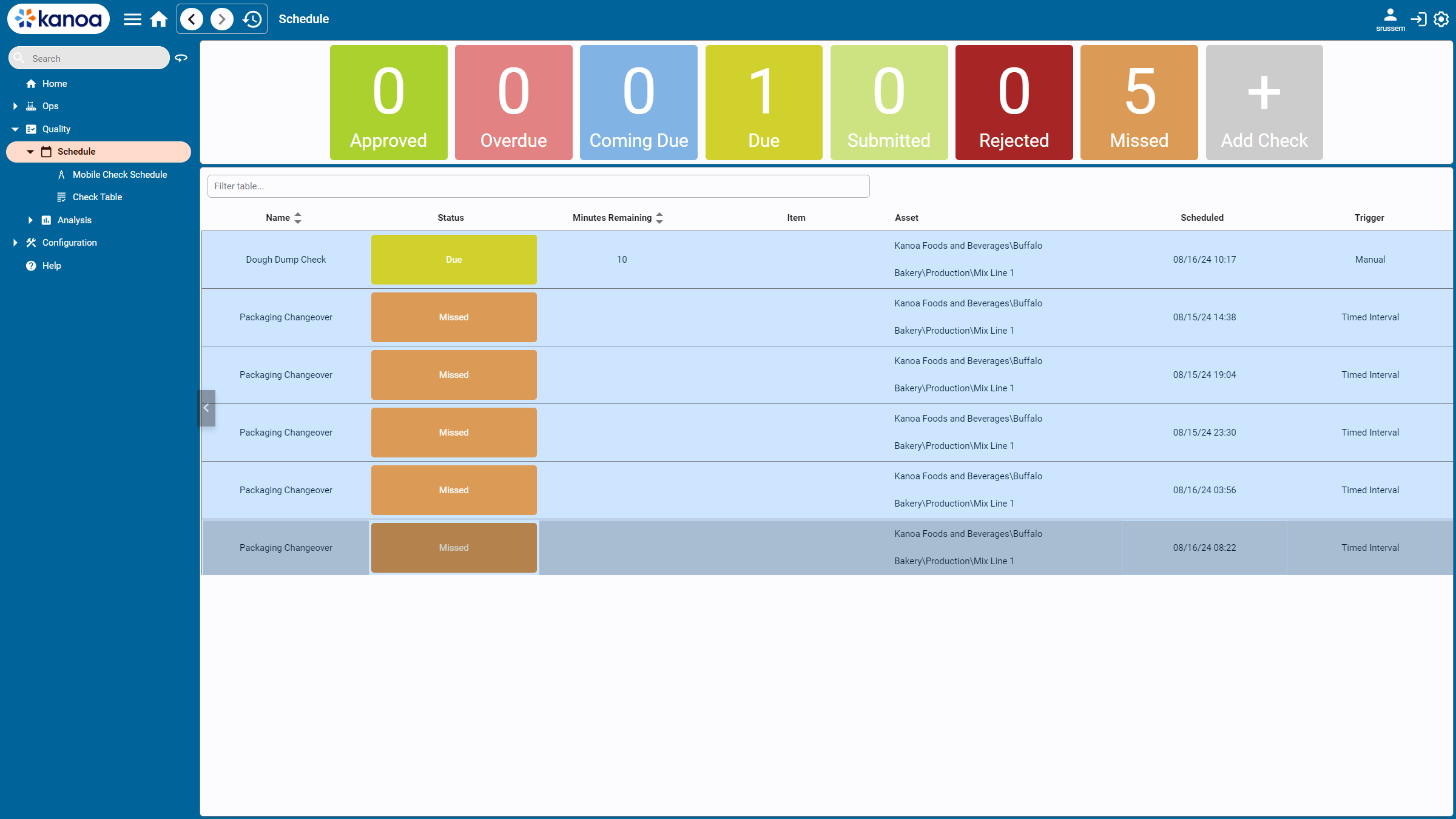

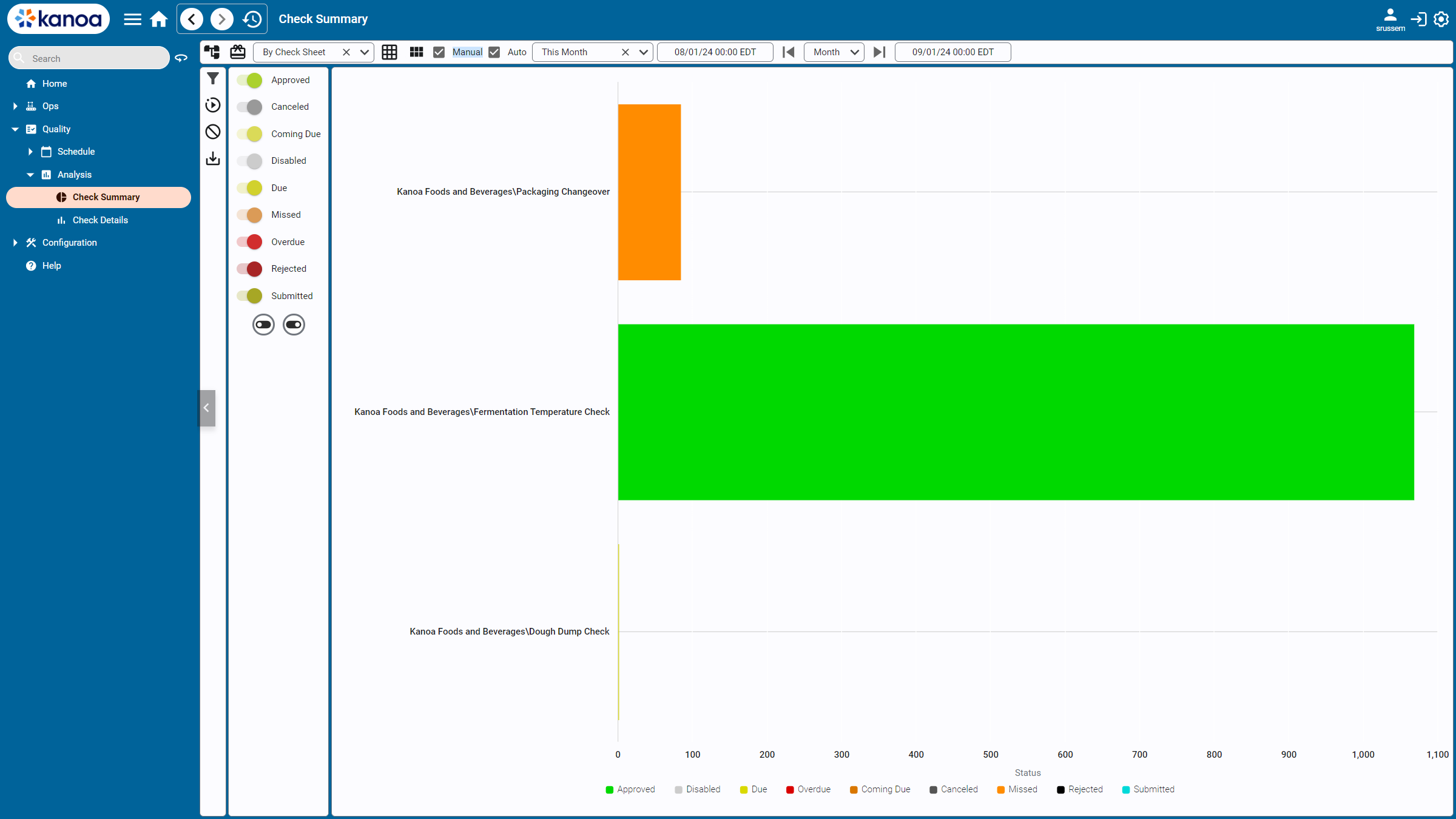

Dispatching & Compliance

Schedule Check Sheets to be dispatched according to your schedule or production conditions. Monitor and alert operators to all outstanding checks from the Quality Dashboard. Analyze compliance with built-in Quality Performance Analysis Dashboards.

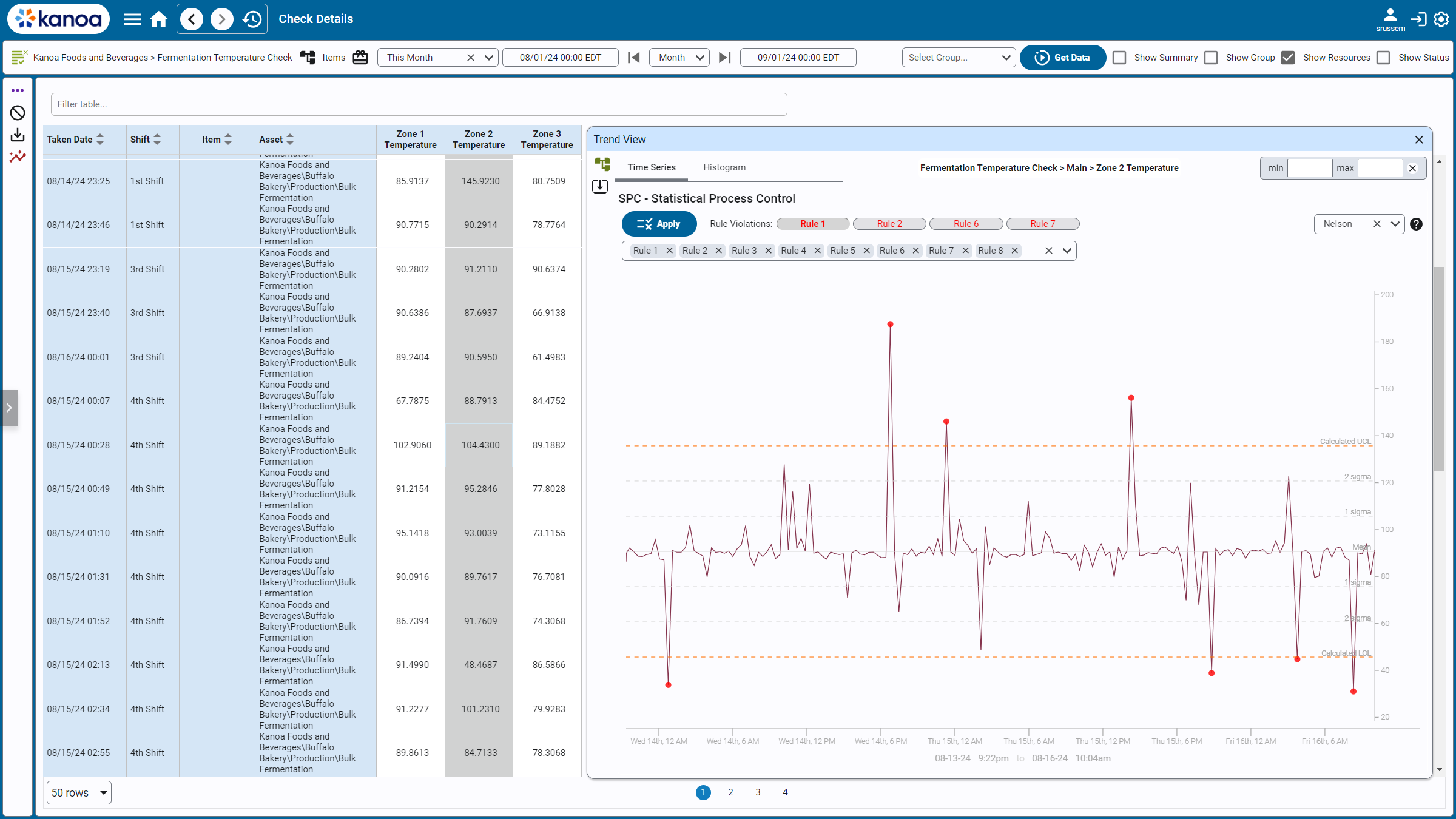

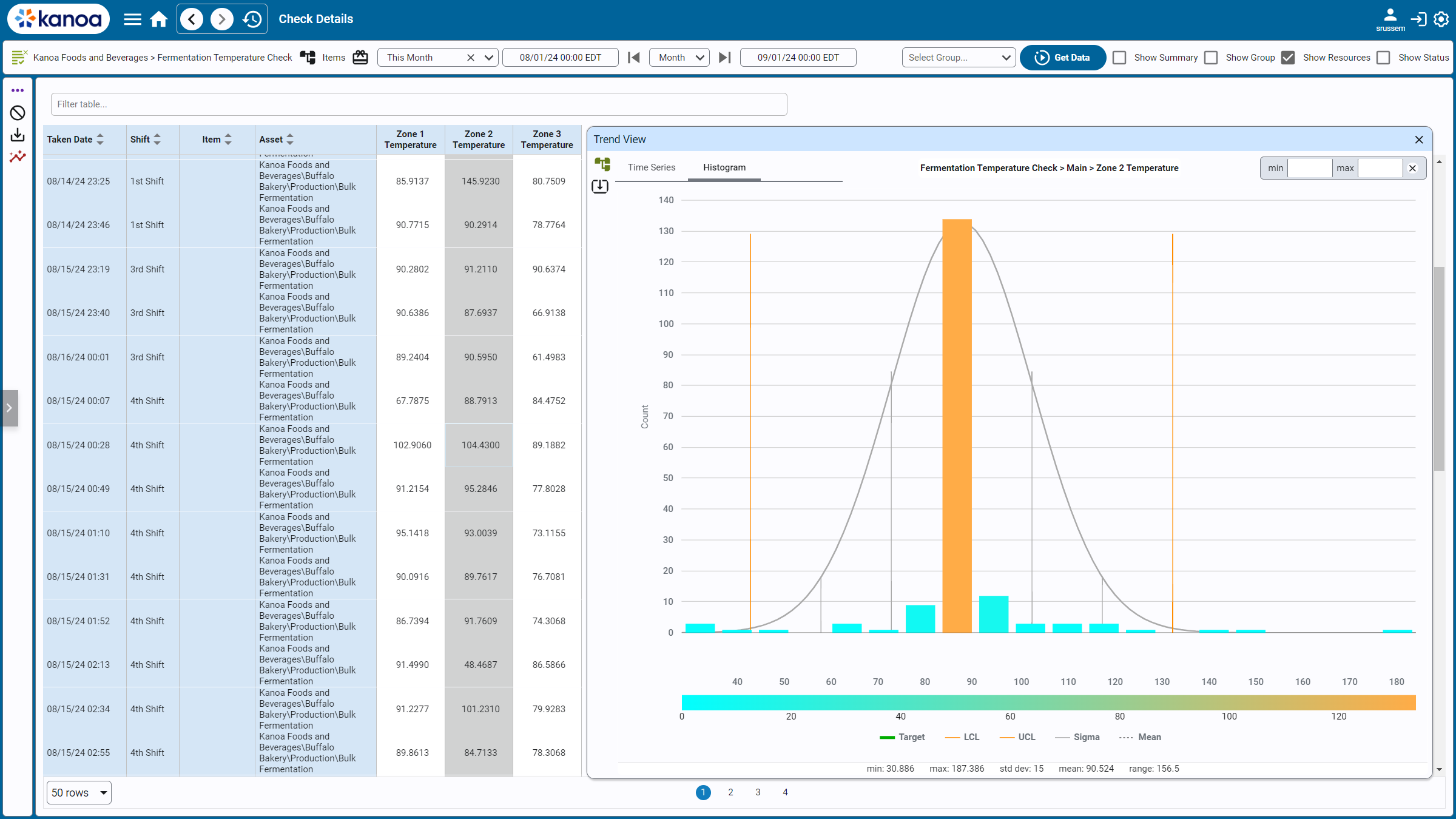

SPC & Data Analysis

Kanoa Quality has quality data analysis, Statistical Process Control (SPC), and Histograms built into the platform. Run Nelson, WECO, or Custom statistical rules against data and highlight violations. Exclude outliers and "junk data" to focus on what is important.

Configure, Don't Code

Kanoa Quality Check Sheets are completely designed in-app; no coding required! Design forms using Kanoa's built-in editor. Assign tolerances, create triggers, add instructions, and more.