Explore the Kanoa Trace Showcase Demo: Full Traceability in Action

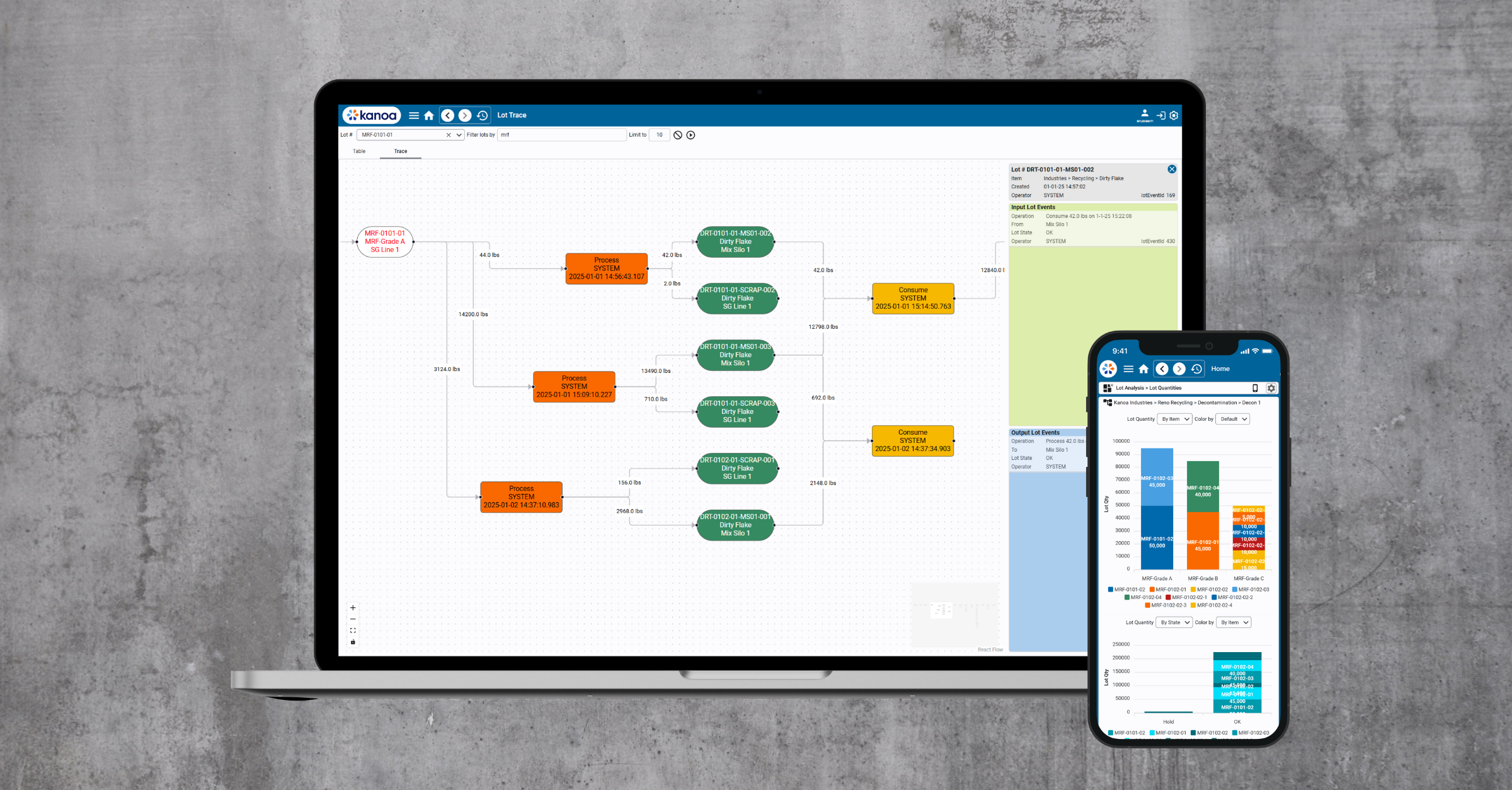

Check out the new Kanoa Trace Showcase Demo, now live on our website! This new, interactive demonstration highlights the power of Kanoa Trace, our advanced traceability software designed to provide manufacturers with unparalleled visibility and control over their material and production flows. The Kanoa Trace Showcase takes you on a guided tour of a fully simulated manufacturing process—bringing the capabilities of our software to life.

What to Expect in the Demo

The Kanoa Trace Showcase is broken into three key areas, each demonstrating unique aspects of our traceability solution:

-

Lot Overview

Explore our help documentation on the foundational elements of Kanoa Trace. Learn how Kanoa Trace tracks raw materials, work-in-progress, and finished goods to deliver real-time genealogy and compliance data. -

Recycling Demo

This walkthrough provides an in-depth look at the Reno Recycling process. From sorting and grinding to washing and decontamination, you’ll see how Kanoa Trace captures every material transformation in real-time. -

Kanoa Ops Integration

Discover how Kanoa Trace works seamlessly with Kanoa Ops to create a unified solution. By combining traceability data with operational context—like production orders, schedules, and asset hierarchies—we offer a complete picture of your manufacturing process.

Welcome to Reno Recycling: The Demo Plant

For this showcase, we’ve simulated a fully operational recycling plant—Reno Recycling—as the demo environment. Reno Recycling processes bulk plastic recyclables into high-quality plastic flake, ready for reuse in new products. This plant serves as the perfect example to highlight Kanoa Trace, offering:

- Discrete processes, such as receiving and preparing bales of recyclables.

- Batch processes, like washing and decontamination.

- FIFO material flow, utilizing storage silos for efficient inventory management.

The result? A detailed view of a 24/7 recycling operation with full forwards and backwards traceability. Start with any received bale of recyclables and trace its journey through the plant to every finished bag of flake it contributes to—or begin with any bag of finished flake and trace it back to the raw materials that created it.

Reno Recycling Demo Process

The Reno Recycling demo illustrates how Kanoa Trace manages traceability at every step of the recycling process. Here’s a detailed look at how it works:

-

Sort and Grind

Bulk plastic recyclables are loaded into the Sort and Grind area, where they are sorted into usable and unusable material. Usable plastics are ground into Dirty Flake, stored in Mix Silos, and tracked with precise lot data. All materials flow in a FIFO system, ensuring a transparent inventory. -

Washing

The Wash Line processes Dirty Flake to create Washed Flake. This involves two steps:- Consume Operation: Dirty Flake is pulled from the Mix Silos and stored as Work in Progress (WIP) in the Wash Line.

- Wash Operation: WIP is cleaned and transformed into Washed Flake, stored in QC Silos for further processing. This two-step approach ensures traceability for every batch.

-

Decontamination

Washed Flake is processed in the Decontamination Line to produce PET flake. The system tracks outputs—stored as Supersacks of PET-A or PET-B—and records any scrap generated during production. Supersacks are prepared for shipment from the Warehouse. -

Warehouse and Shipping

The Warehouse serves as the central hub for raw materials and finished goods. Incoming recyclable bales are logged as new lots, and finished Supersacks are staged for shipment. With Kanoa Trace, you can follow every lot from start to finish, including truck loading and departure.

Business Value: Why Traceability Matters

The Reno Recycling example highlights just a few of the benefits manufacturers can gain with Kanoa Trace:

-

Regulatory Compliance

Maintain complete records of material genealogy to meet industry regulations and standards. -

Quality Control

Quickly identify and isolate issues in your production process, reducing downtime and improving product quality. -

Efficiency & Waste Reduction

Gain insights into material flow and inventory management, enabling better decision-making and reduced waste. -

Customer Assurance

Provide end-to-end traceability to build trust and confidence with your customers.

Experience the Future of Manufacturing

This read-only demo is designed to give you a sense of what Kanoa Trace can bring to your operations. Whether you’re focused on quality, compliance, or continuous improvement, Kanoa Trace is here to help you achieve your goals. And this is just the beginning—our vision includes expanding the demo to other simulated manufacturing environments in the future.

Ready to take a closer look? Visit our Kanoa Trace Showcase Demo today and see how our software can revolutionize your manufacturing process.

You May Also Like

These Related Stories

Introducing: Kanoa Trace

%20(9).png)

Precision Lot Traceability from Raw Material to Finished Product with Kanoa Trace

%20(2).png)

No Comments Yet

Let us know what you think